All these elements are part of the control system which, depending on the set input parameters dependent on the type and humidity level of the dried material, automatically maintains the selected drying conditions, i.e. temperature and speed of material movement in the dryer. The dryer is adapted to work as a stand-alone device and can work as an element as an element of a technological line, where it can be connected to the superior control system of the production plant.

Drying is one of the elementary stages of processing bulk materials in all industrial sectors. Bulk goods such as sand and gravel, coal, crystal products, food products and animal feed etc., as well as waste products must be properly dried before they are introduced into further processing or final processes such as product packaging.

The key factors, apart from the reliability of each type of industrial equipment, are their high efficiency while reducing operating costs and production costs as much as possible.

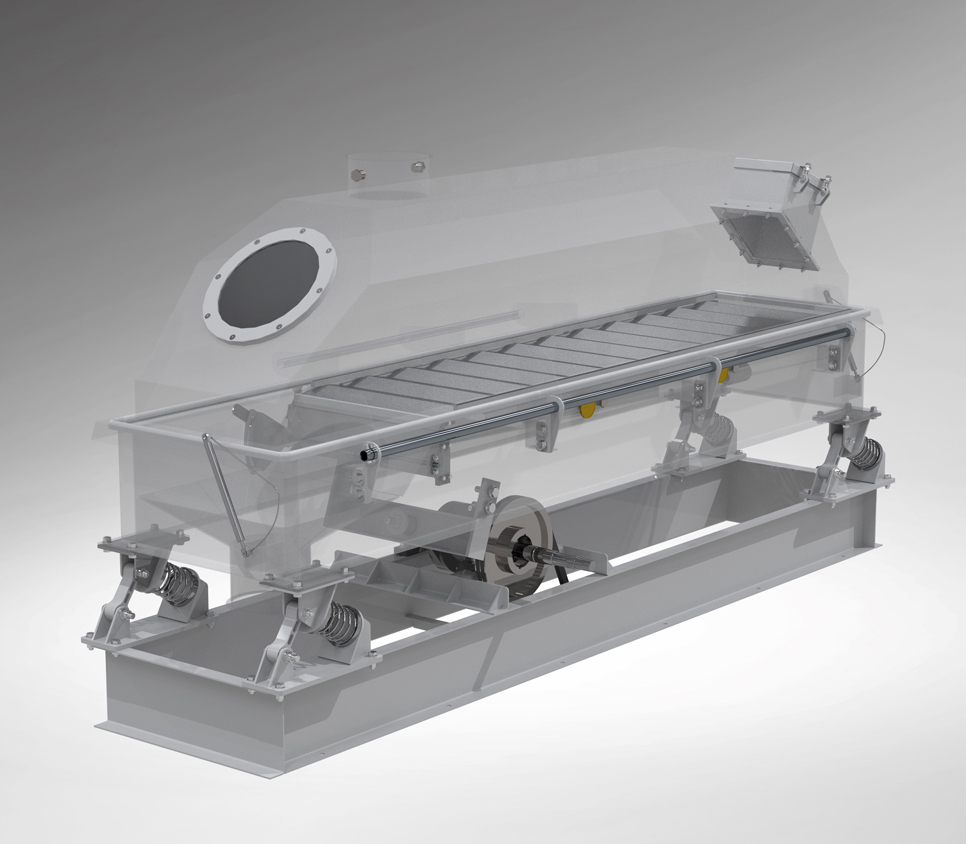

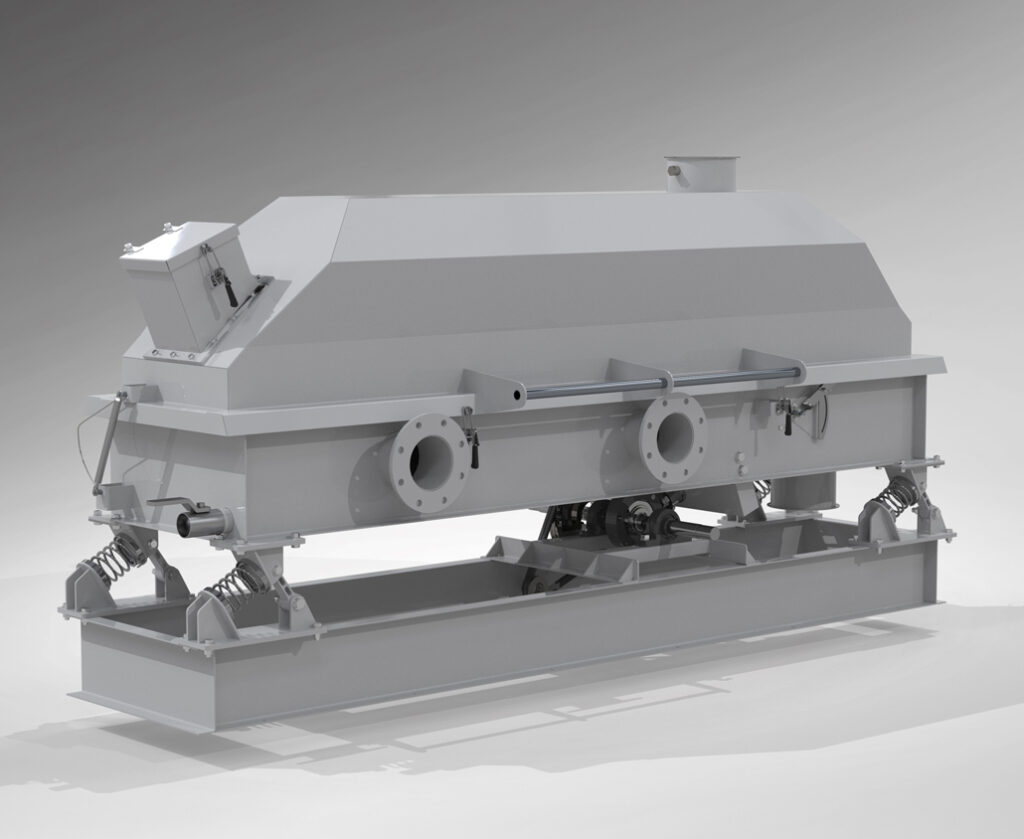

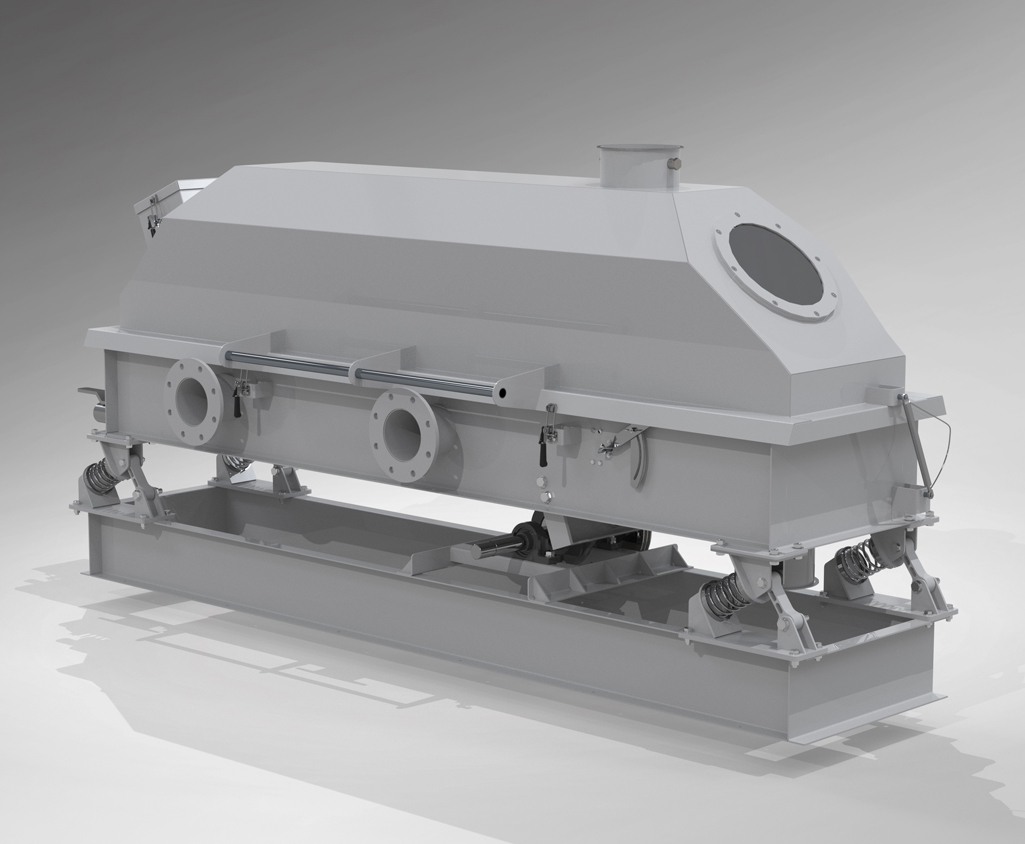

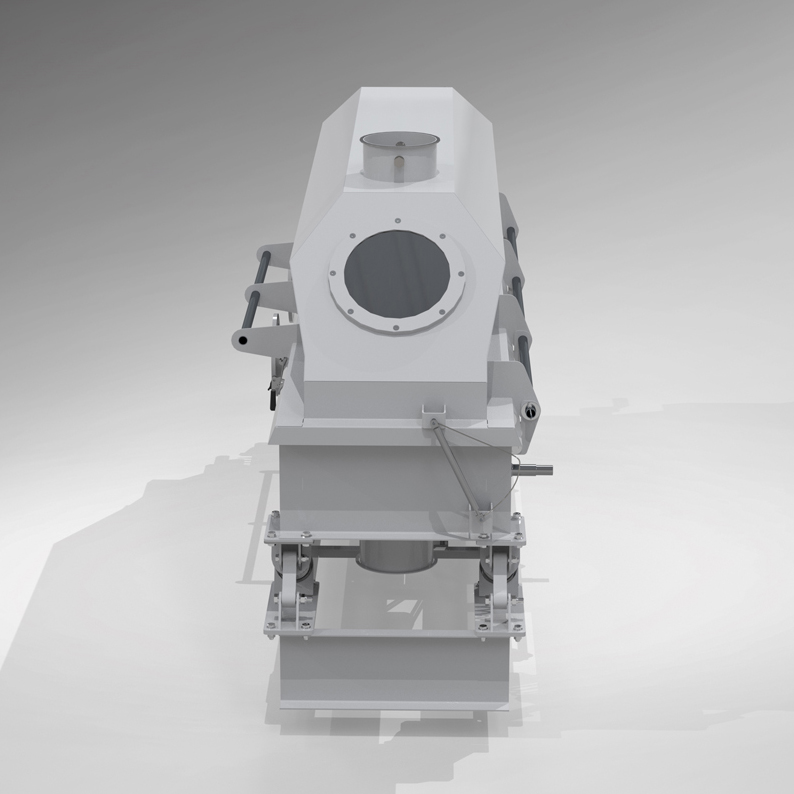

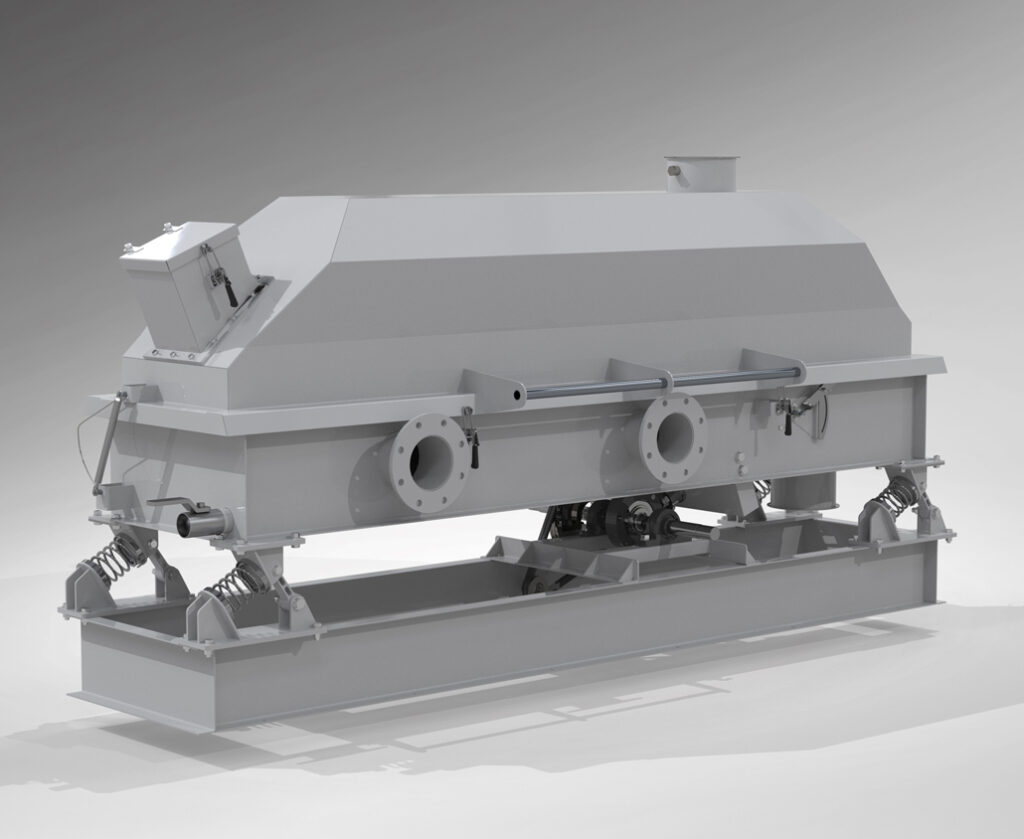

Vibrofluidic dryers have a number of significant advantages over e.g. chamber, shaft or drum dryers: the above-mentioned process efficiency, more optimal use of energy, more uniform drying of the material thanks to its vibrations, simple process control and monitoring of the drying temperature, maintaining a high sanitary standard, possibility of easy cleaning of the device and carrying out service and maintenance activities, possibility of quick change of the processed medium, reduction of the risk of damage to the dried material due to the very gentle handling of the product.

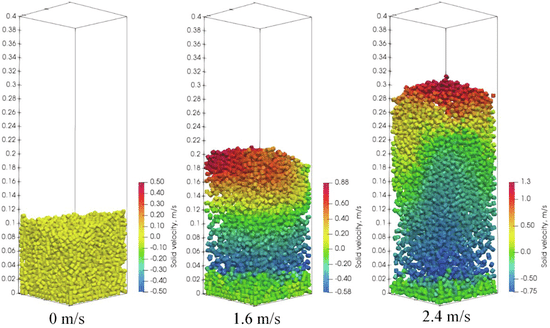

Vibrofluidization dryers base their operation on the phenomenon of fluidization, i.e. the process of creating the so-called dynamic suspension (fluidized bed) – small solid particles in a gas stream moving from bottom to top.

Fluidization allows you to create a large contact surface between the solid and gaseous phases, the so-called interphase contact. The fluid bed dryer is the most energy-efficient solution, especially in the case of a continuous operation system.

Particles in the fluidized phase are in constant motion, moving constantly throughout the entire volume of the dryer, which gives the impression that this layer behaves like a “boiling liquid”. The fluidization phenomenon is used to conduct technological processes that require a large interfacial surface and rapid heat exchange.

Fluid bed dryer technology is intended mainly for drying loose products and granulates, but not only that. We often deal with a product in which the size of individual particles differs significantly and the humidity is high. By combining the appropriate gas flow speed and mechanical movement, loose products with a wide range of particle sizes can be processed, while generating negligible amounts of dust.

During this process, air flows around each individual particle. The resulting large contact surface between particles and air ensures optimal heat and mass transfer and thus enables quick, gentle and energy-saving drying.

The air cushion between the particles prevents abrasion and agglomeration. The vibration of the bottom supports the fluidized bed and has a very beneficial effect on the drying process.

The operation of the fluidized bed dryer involves supplying warm gas/air to the perforated deck where the raw material or product to be processed is located. The supplied medium causes the formation of the so-called fluidized bed, which acts on the product and causes it to dry. High temperature and increased pressure are created in the fluidized bed dryer deck. Additionally, for difficult products, appropriate vibration movement provided by the fluidized bed dryer causes controlled movement of the product in order to obtain an optimal fluidization process. In this drying method, the product is intensively mixed with gas, which guarantees high heat transfer and optimal speed of physical processes. Fluid bed dryers are suitable for drying temperature-sensitive products and products with increased viscosity. Fluid bed dryers can create pre-fluidization conditions that prevent burns and discoloration of the material undergoing the drying process.

The fluid bed dryer is used for the processing and refining of waste products for their reuse, e.g. in the production of animal feed or the processing of grain sludge from breweries. Another use is for drying coarse minerals such as sand and gravel. Our engineers have developed fluidized bed dryers to ensure optimal results while minimizing abrasion. The unique drive allows us to create a fluidized bed as large as the product requires.

A version with a gas recirculation and closed loop system is also available for improved efficiency and recovery. The materials used in production ensure durability and functionality in use, while meeting even the strictest technological and sanitary requirements. All size and functional parameters of our fluid bed dryers are adapted to the requirements set by our customers.

By providing heat and gas flow through the dried substance, we are able to reduce the amount of a given solvent / binder (usually water) in the product. Drying in industry changes the physicochemical, organoleptic and microbiological properties of substances. It is used primarily to reduce humidity, weight and size. This is one of the oldest ways of preserving food products. If properly carried out, the drying process can retain most of the original characteristics of the product. For the correct drying process to be carried out, it is always necessary to select the appropriate drying method in terms of technology and then the device to obtain the optimal energy and economic effect.