Biko Tech is a manufacturer of steel silos and supporting structures adapted to them, and a leading manufacturer in Poland of silos with a small cone angle, which consists of modular elements.

Steel silos are primarily used to store materials and raw materials, both finished and semi-finished products. These are devices used in most industries and production.

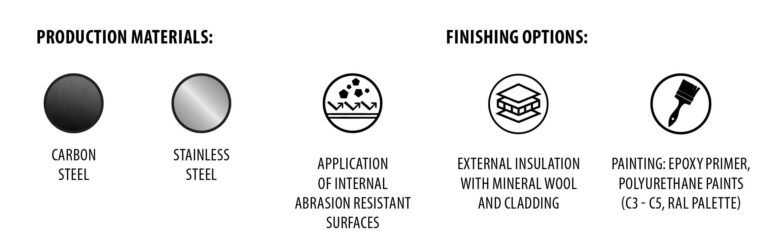

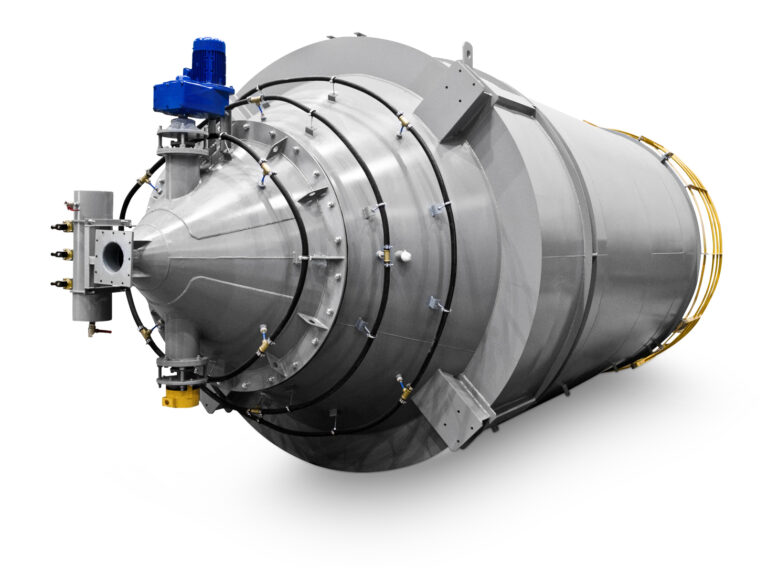

The production of steel tanks is an extremely important area of industry that plays a key role in storing and transporting various substances. The production process of Biko Tech steel tanks begins with their careful design by the Engineering and Design Department. Engineers take into account all parameters such as capacity, pressure, temperature and the type of substances that will be stored. The project must also meet all standards and regulations regarding safety and compliance with industrial and construction standards. Then the process of cutting and forming the steel sheet begins. Advanced technologies and modern machinery allow high precision in the production of tank elements. The individual prefabricated elements are then joined to create the tank body. The welds are carefully made, ensuring the durability and tightness of the structure.After assembling the body and individual cargoes of the tank, its surface treatment begins. Grinding and polishing not only improves aesthetics, but also protects welds against corrosion. Additionally, the tanks can be equipped with thermal insulation, which helps maintain a stable temperature inside the tank. The next step is to install additional elements, such as safety valves or systems for monitoring stored substances. Depending on the purpose of the tank, various accessories can be used, adapted to the physico-chemical properties of the stored substance. The entire production process of steel tanks is subject to strict quality controls to ensure that the finished product meets all standards and expectations of our Customers.

Proper storage of products and semi-finished products is a technologically necessary process that allows them to maintain their high quality. Determining the silo fill level is a key issue related to storing various types of material in them. A rational storage policy is a key element of the functioning of every industrial installation.

Thanks to the knowledge of how much of the silo is filled, we will avoid overfilling it. Smaller silos can also act as buffer tanks from which industrial installations take semi-finished products necessary for the continuous operation of the technological line.

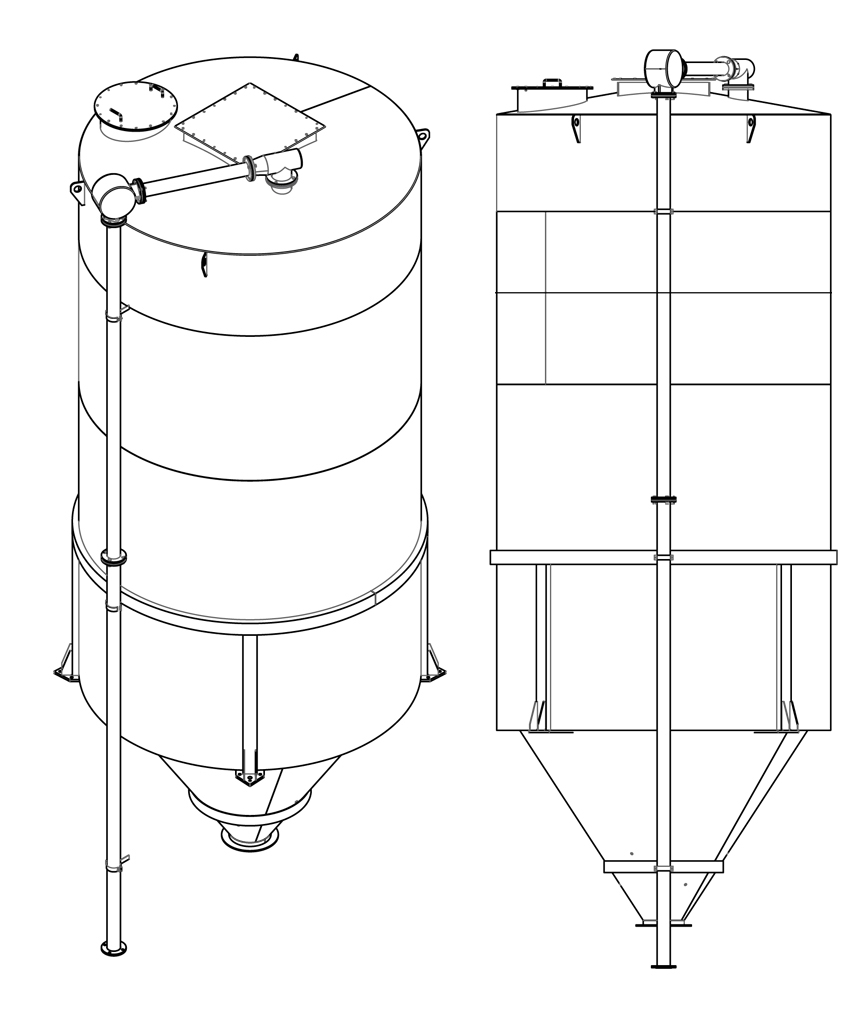

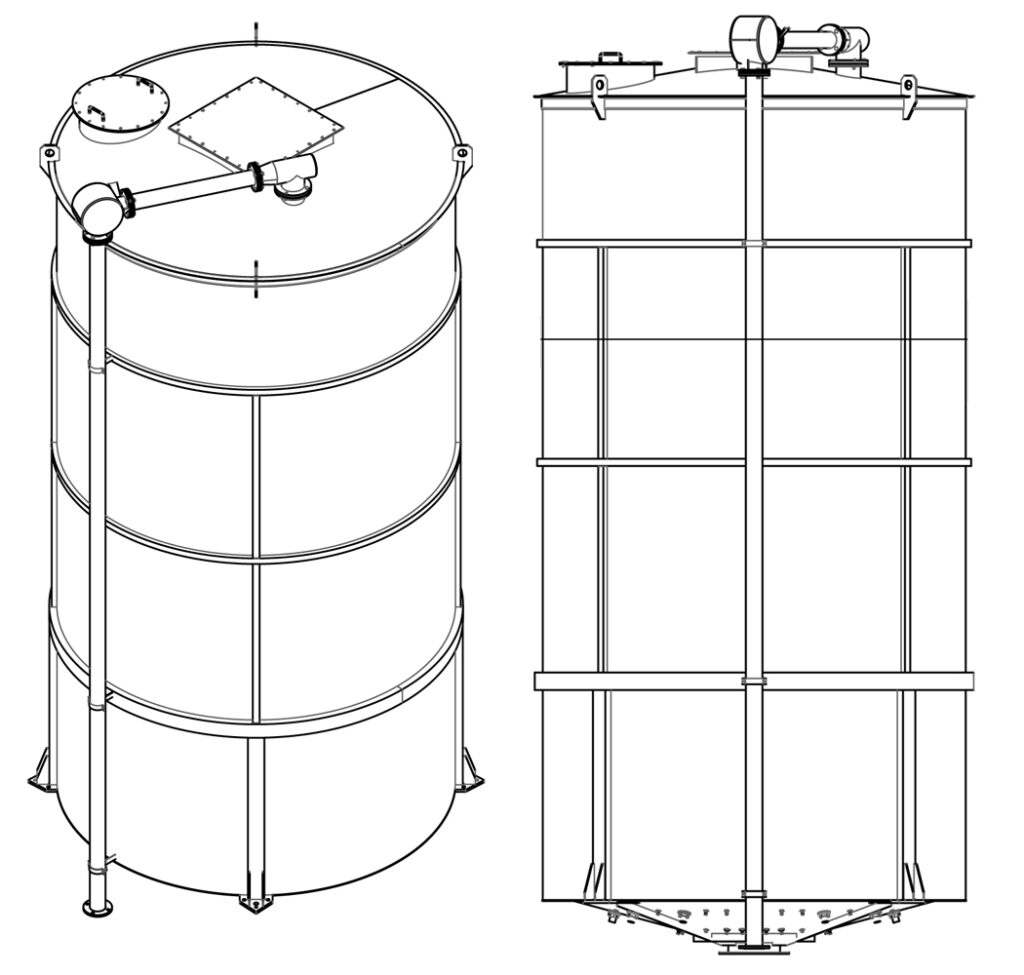

Silos intended for storing hygroscopic materials, such as cement, flour, artificial fertilizers, coal dust, industrial ash, lime or some fine-grained or fibrous raw materials, and plastics, usually have a specially adapted geometry and wall texture. The inclination of the discharge hopper walls is selected in them to make emptying the tank as easy as possible.

Depending on the material stored in the silo, these tanks can be equipped with various types of BKDU unloading assistance systems, also known as deagglomerators.

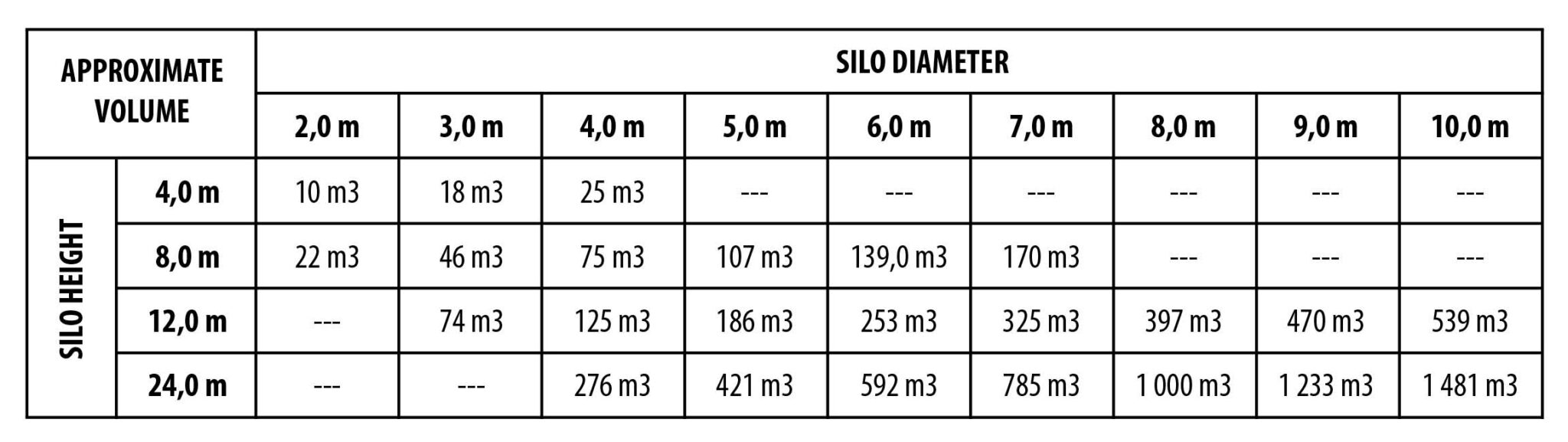

BKSS steel silos are commonly used in almost all branches of industry and agriculture around the world. They are used for temporary or long-term storage, warehousing and warehousing of bulk, dry materials, product mixtures and granulated products. They are also ideal for storing agricultural products such as cereal grains, rapeseed, corn, etc. Silos are divided into flat-bottomed, funnel-shaped and tower silos. The greatest advantage of silos is the ability to store a large amount of materials while using a relatively small amount of space. Silos, thanks to the fact that in most cases their capacity is increased by vertical expansion, can be placed in places where it would otherwise be impossible. Silos are also very good protection for the goods stored in them. They provide protection against atmospheric factors and pests, but also provide adequate humidity and ventilation, which are very important factors when storing bulk products. Silos are very resistant to physical damage and, most importantly, fireproof, which is a very important feature of these structures. The solutions proposed by our company are tailored to the individual needs of the customer, we can offer the production and assembly of tanks of various sizes and shapes, made in one piece or assembled on site. We offer typical solutions optimized in terms of costs: fully welded and bolted, as well as non-standard tanks adapted to the material and production process.