Screw conveyors are an important element of many production processes. They are used to move materials from one place to another, often in a continuous flow, over relatively short distances, between devices that are components of a production or industrial installation.

Screw transport is considered one of the most reliable methods used in manufacturing, industrial and agricultural industries. These devices are widely used in the chemical, construction, agricultural, energy and waste management industries.

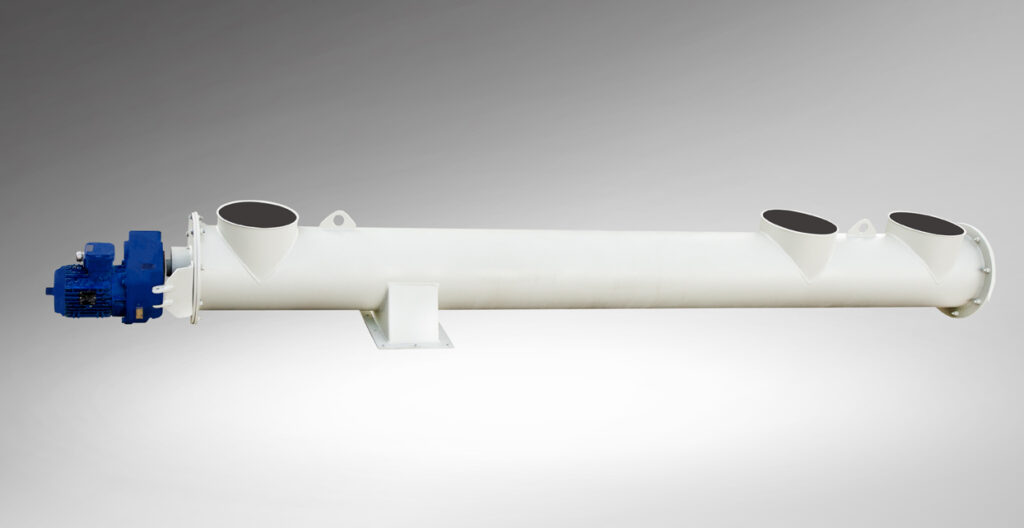

The BKSC screw conveyor manufactured by Biko Tech is intended for the transport of dust and all kinds of loose and finely divided materials, such as: cement, alternative fuels, pea and fine coal, seeds, feed, etc.

Screw conveyors can collect material transported from hoppers, unloading hoppers, tanks or other conveyors and feed it to other unloading devices or silos and tanks. Screw conveyors allow material to be transported horizontally, at an angle or even completely vertically.

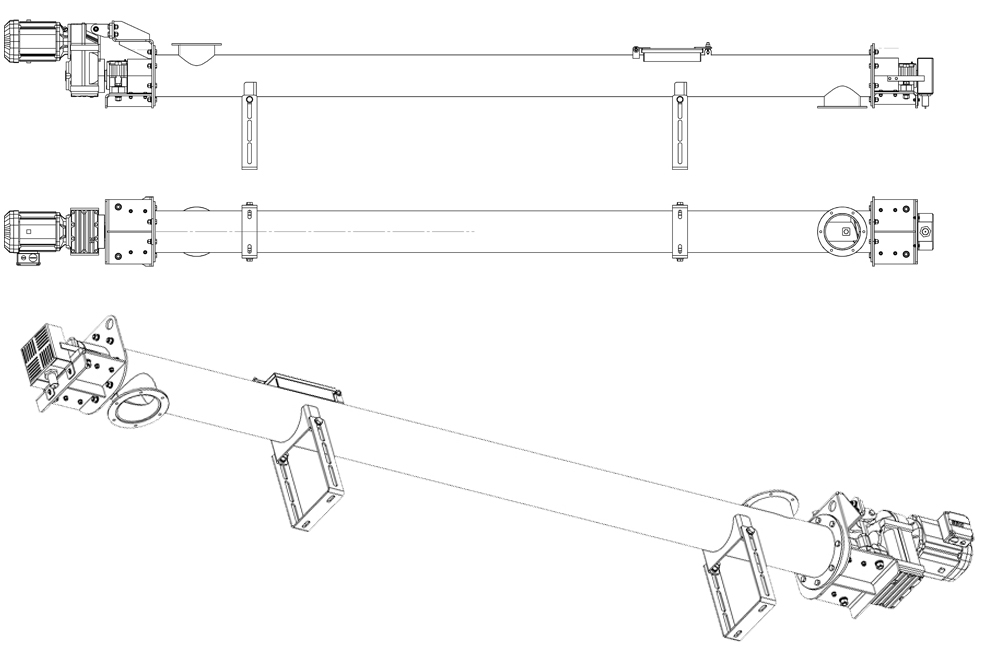

Each such structure has a screw inside. Its shape resembles a ribbon or a set of blades – depending on the device model. This element is most often attached to the shaft, although in some models this part is not present. The circular movement of the ribbon or blades causes the load to move in the intended direction.

Screw conveyors are made in two basic versions: trough and tubular. There are also two-shaft versions or those adapted to transport medium at high temperatures. In the reversible version, the screw conveyor allows material to be moved in both directions. The direction of material movement is changed by changing the direction of rotation of the screw shaft. Biko Tech produces innovative screw conveyors (vertical and horizontal) with high efficiency and low energy demand.

Biko Tech is able to design, conduct digital simulations of the process using DEM methods, produce and test prototypes of screw conveyors in order to optimize them in terms of energy consumption or achieve the required performance and operating characteristics. We also offer the possibility of regenerating existing devices.

The combination of high-quality materials and simple construction results in reliability. Conveyors made of stainless steel are resistant to corrosive factors, making them durable and long-lasting. For demanding transport processes of semi-finished products or abrasive raw materials, the screw coils are made of steel with increased abrasion resistance, e.g. hardox steel.

An additional advantage of screw conveyors is the simplicity of their installation, the ability to work in difficult conditions and low operating costs. We produce screw conveyors only from high-quality materials. We offer a wide range of sizes and designs, which allows us to meet the needs of almost every industry. Thanks to our experience and knowledge, we can help you find the perfect solution for your production and industrial installation.

Our solutions are based on the results of simulations of the actual behavior of bulk and lump materials using the Discrete Element Method (DEM). We are one of the few European companies using DEM capabilities in designing devices.