Biko Tech flow control gates / valves are dosing equipment designed to ensure controlled unloading of bulk materials from silos and containers. They are installed at the outlets of hoppers under dust removal devices, devices for aeration transport or bulk material tanks. These devices are used to dose, regulate the flow and cut off the transported dry dust, bulk and fine-grained materials. Flow control valves are widely used in cement silos to regulate the flow of material from the silo to further devices.

This type of flow control valve has been designed specifically for all applications where the space under the silo is limited. It is possible to dose any bulk materials capable of fluidization, e.g. fly ash, cement or aluminum oxide.

The dosing capacity is regulated by the rotation of the dosing device cylinder, which changes the area of the inlet-flow opening, and thus regulates the flow and dosing values.

Depending on the application, bowl gate valves can also be used in applications such as loading, packaging and weighing products.

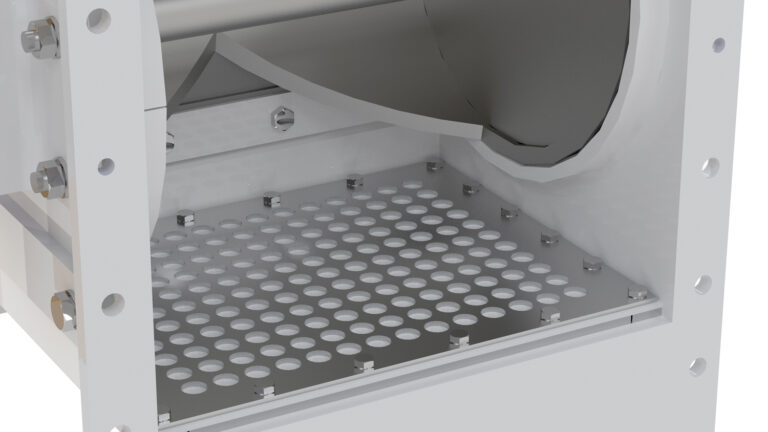

The flow control valve has two chambers inside. The lower chamber supplies fluidizing air to the upper chamber. It acts as an air conveyor, maintaining a continuous flow of material. The air-permeable fabric separates the upper and lower chambers and maintains a constant air flow to the upper part.

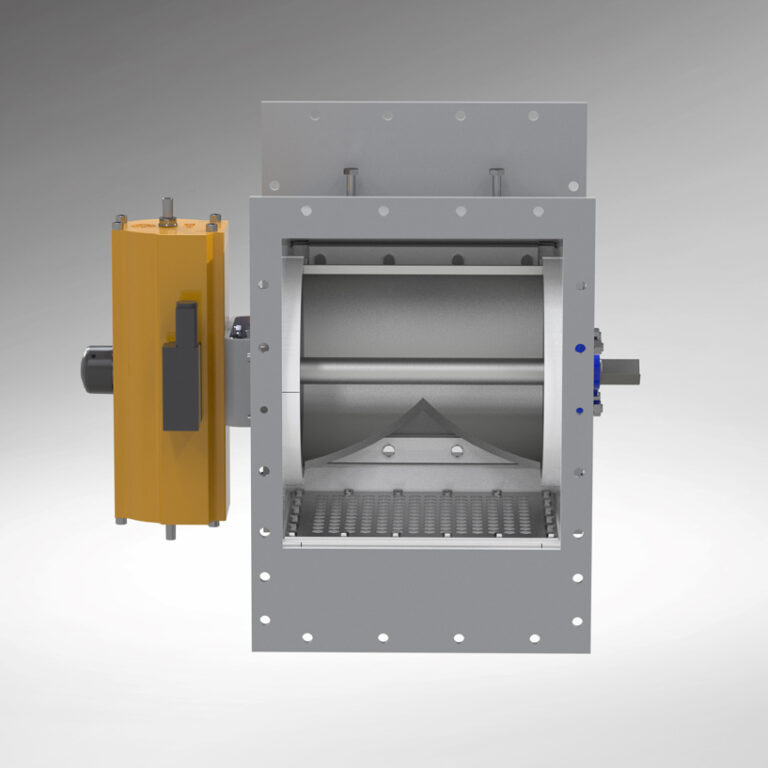

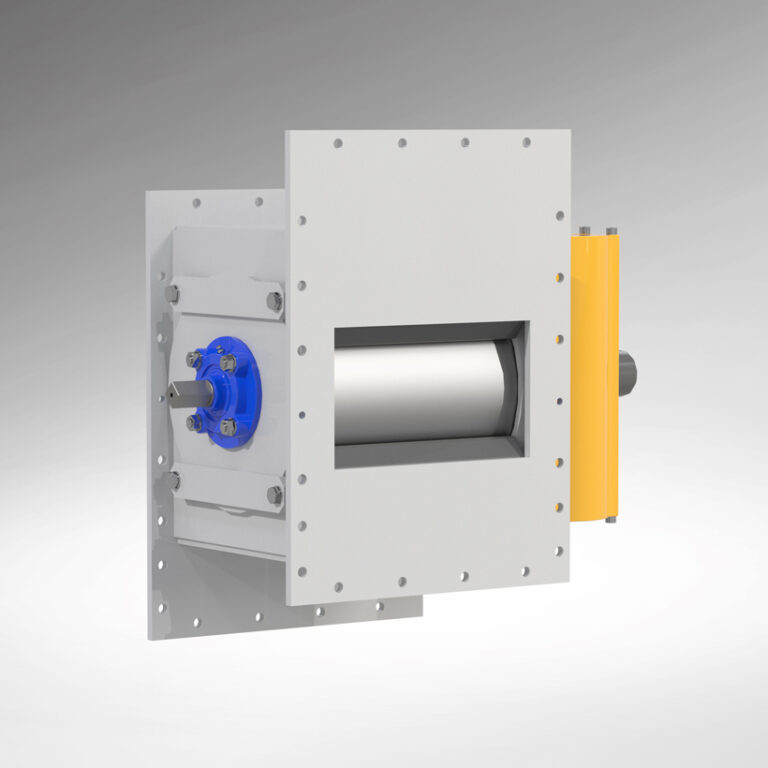

The upper chamber has a rotating drum with an opening on the circumference. Rotating the drum in one direction provides a dust-tight shut-off. Rotating the drum in the opposite direction provides an adjustable cross-section of the material flow. By adjusting the exact position of the drum, the flow rate of the bulk material can be precisely regulated. When the valve is fully open, we have an uninterrupted flow of bulk material.

High tightness and no leaks between the rotating drum and the valve body are ensured by a flexible seal. Welded housing ensures greater durability and reliability of the devices.

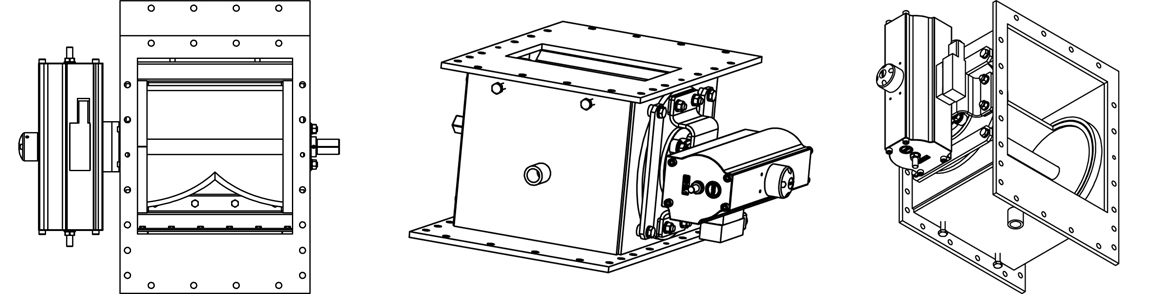

The rotating drum can be activated by a pneumatic piston, electric drive, pneumatic positioner or manual lever. Drum drive systems are designed specifically for each application, allowing very precise dosing or closing, increasing or decreasing the flow and controlling the product outlet cross-section. The position of the rotating drum can be adjusted using a special position regulator to maintain the device’s operating efficiency at the intended level. Built-in limit switches and position indicators allow checking the drum position.

The tightness between the rotor and the body is achieved by means of felt, which ensures excellent sealing and long and trouble-free operation of the device.

The bowl gate valves are easy to maintain and very resistant to wear. The design of the valve is always adapted to the material properties of the transported substance and to the flexible configuration for each type of installation. Custom-designed valve models are available.