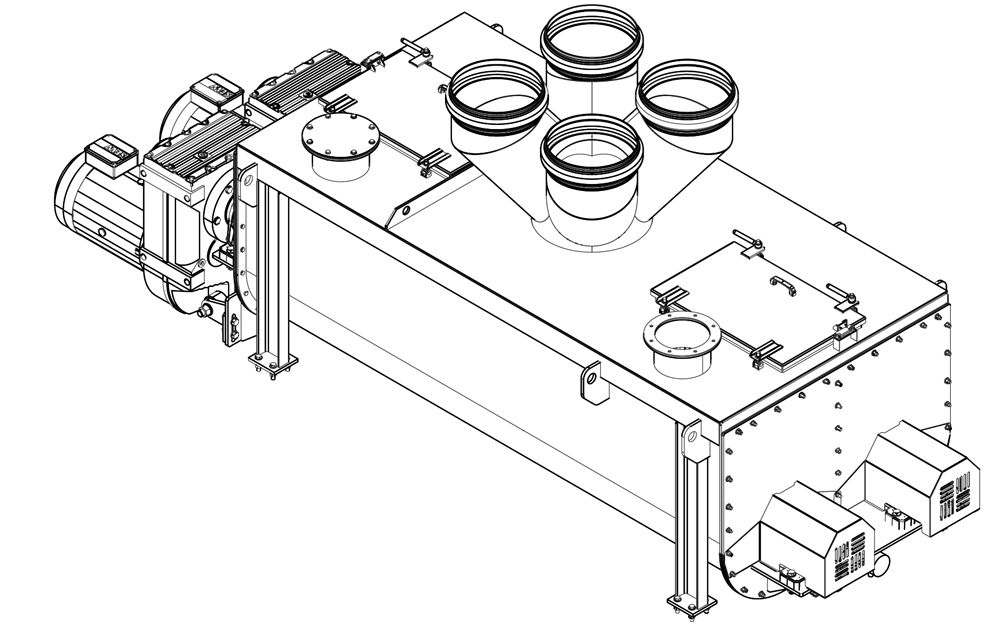

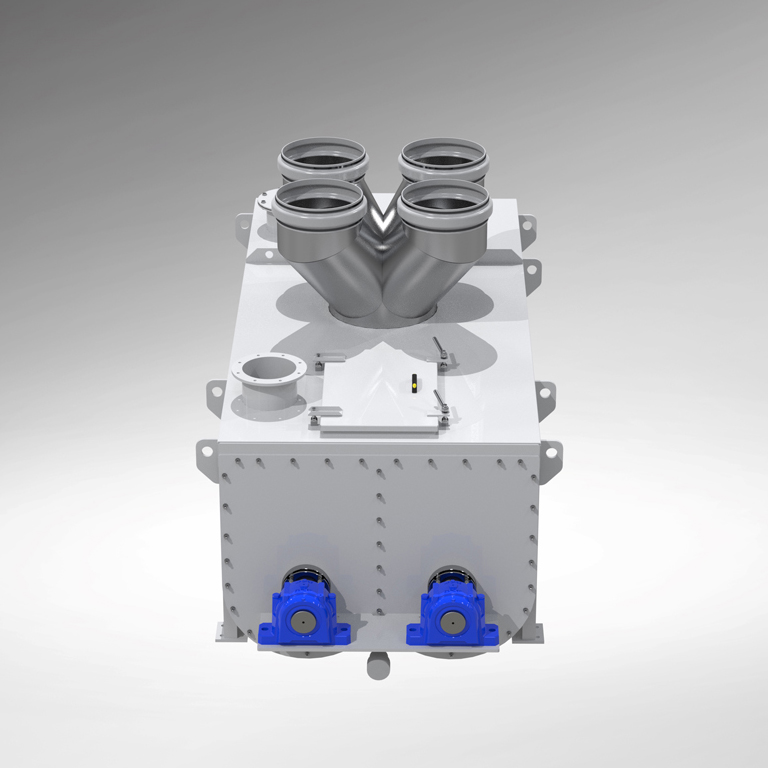

Batch mixers meet all the requirements of Biko Tech customers in terms of high quality and precision of mixing during periodic processes, which are aimed at optimizing the efficiency of the technological line. Wherever the highest possible quality of the mixture and optimal process efficiency are required, the use of BKBM series batch mixers is recommended.

Mixers for batch operation with full opening are used in almost all industries: construction, food, chemicals, animal feed production, etc.

Single-shaft batch mixers are ideal devices for achieving the highest quality mixtures while maintaining repeatable raw material inputs. The construction of batch mixers is simple, but the mixing process itself is quite complicated.

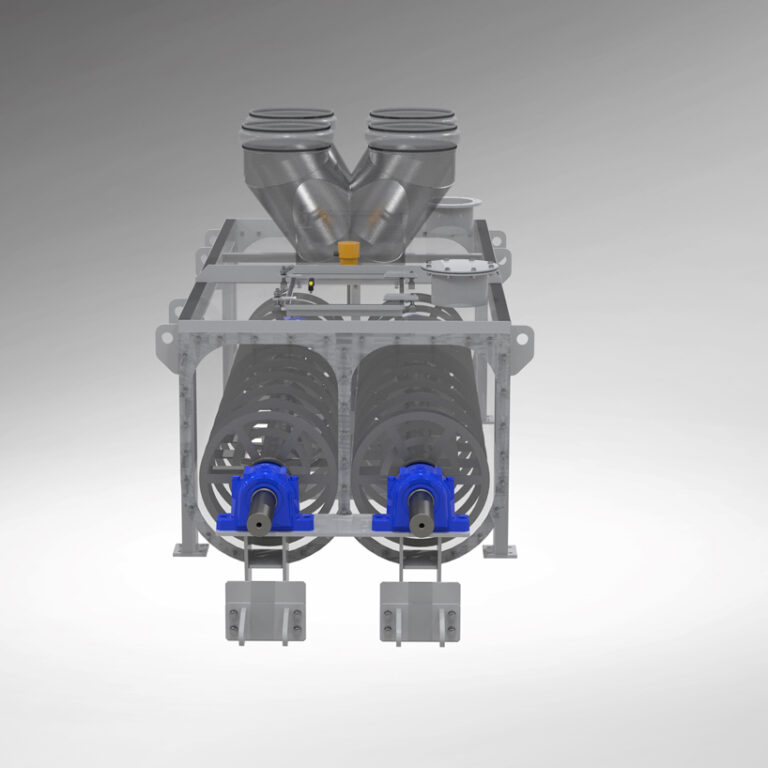

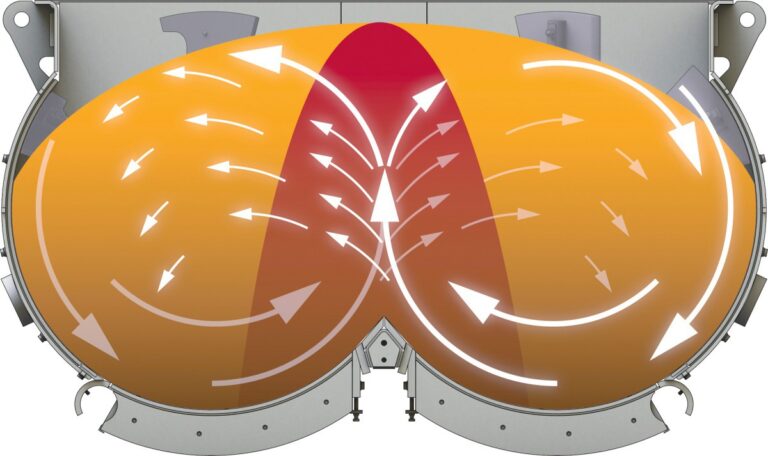

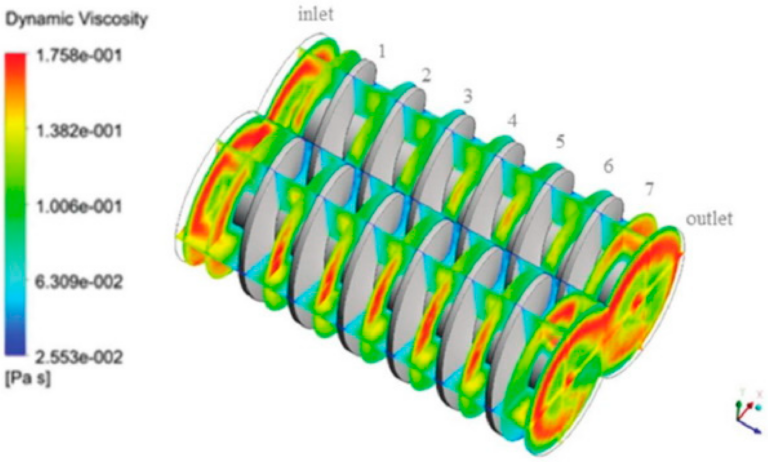

Plow or shovel-type paddle tools rotate in a special arrangement on the mixer shaft in a horizontal, cylindrical drum. The result is swirling of the mixture, which constantly draws all the product particles into the mixing process. The creation of dead spots or slow movement in the mixing drum is avoided, ensuring thorough mixing of raw materials. In some cases, separately driven high-speed knives can be installed to achieve the required mixing effect.

The operation of a horizontal single-shaft mixer for batch operation is based on the principle of mechanical fluidization of the mixed product.

The special shape, position and rotation speed of the mixing tools generates a centrifugal rotational movement, which allows the material to be moved three-dimensionally and combined with other materials. This ensures that ingredients with different particle sizes and bulk densities are perfectly homogenized and mixed with high precision in the shortest possible time.