Granulation, also known as agglomeration, pelletization, is the process of combining small particles such as dust, powders or ashes into larger aggregates (granules), with specific mechanical strength and granule size above 1 mm. The agglomeration or granulation process itself is carried out by wet granulation with the addition of liquid or alternatively by hot granulation.

Granulation is used to obtain a convenient final form of the product that is acceptable to users. Raw materials or semi-finished products are often granulated to facilitate or even enable their use in appropriate technologies.

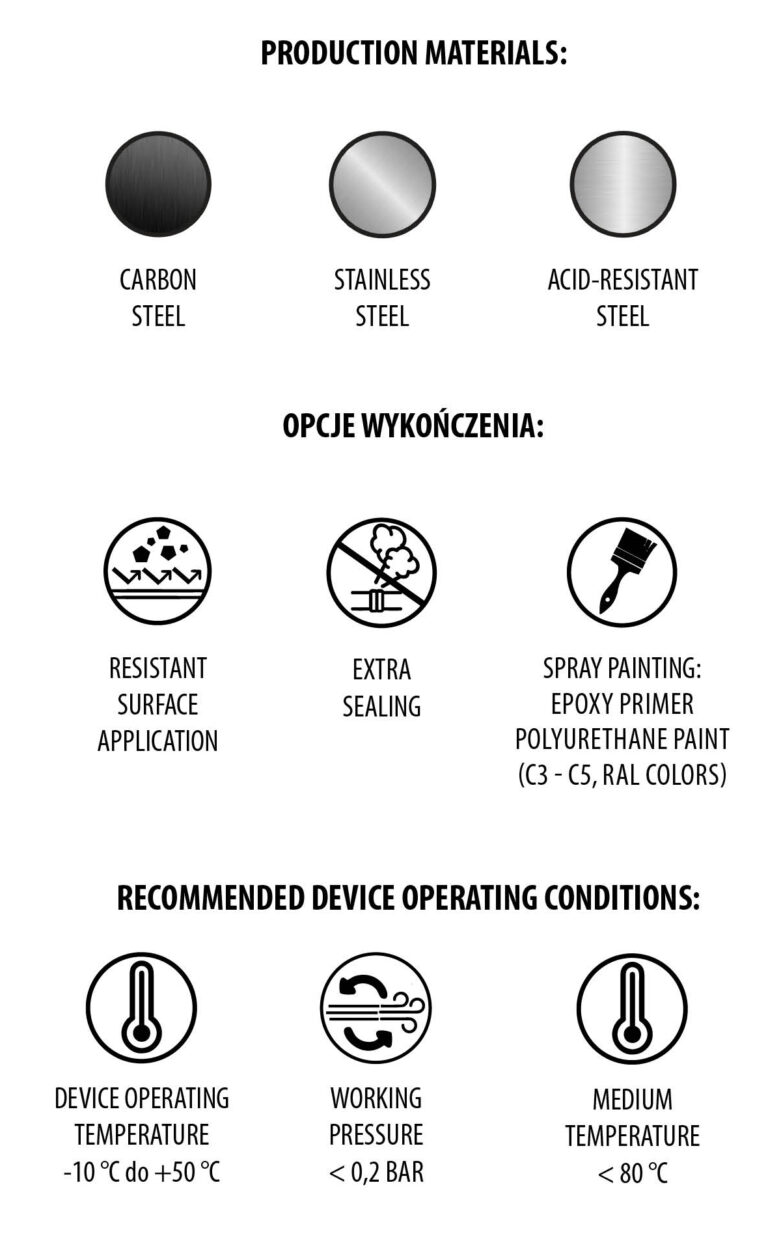

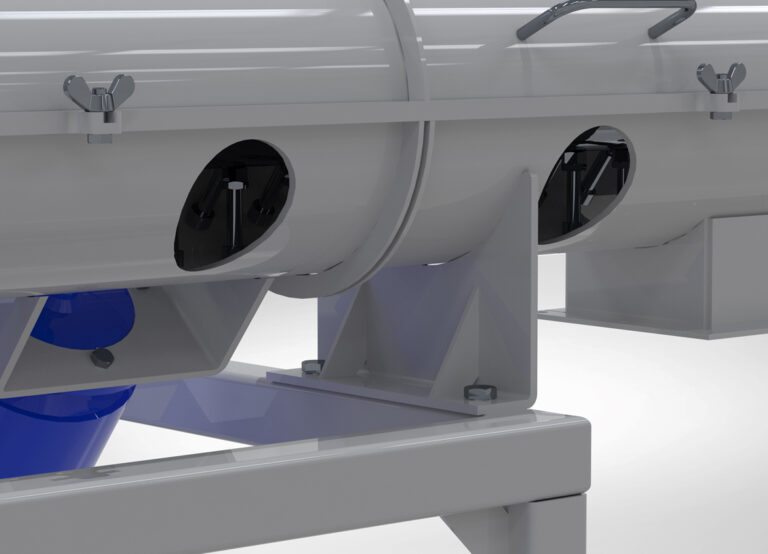

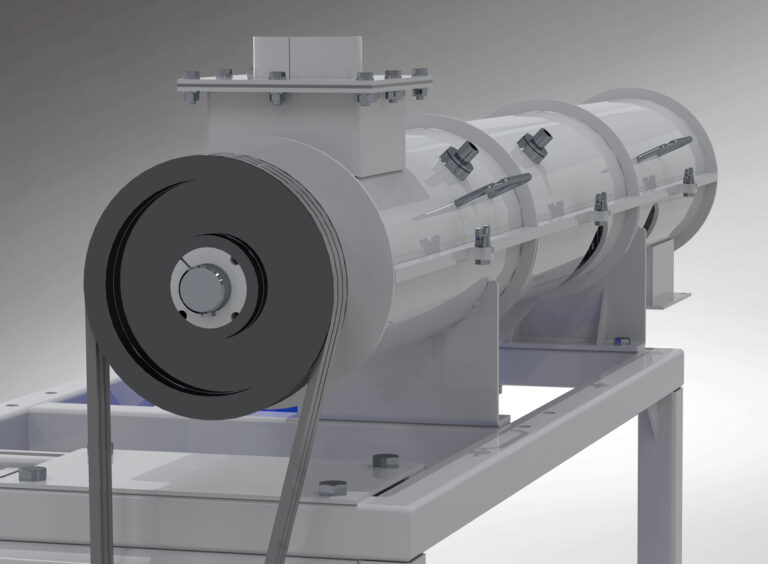

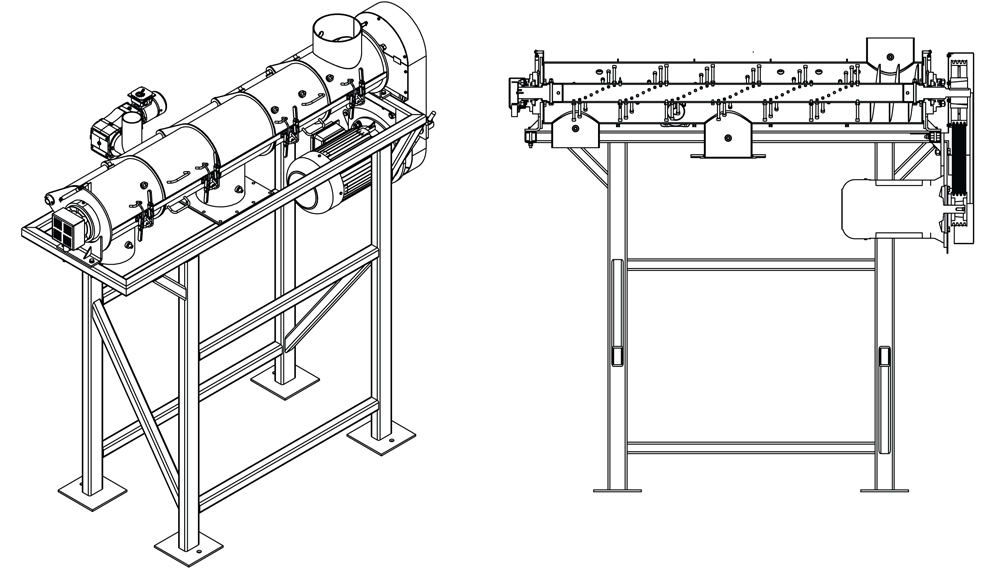

PIN tubular granulators are used for pelletization, micropelletization and homogenization of many types of bulk materials using high-speed pins arranged in the form of a screw. The device operates continuously, achieving much higher efficiency than batch granulators.

Compared to disc granulation, lower product moisture is required (lower demand for binder), higher density and mechanical strength of the granules and a higher share of the desired fraction, up to 98%. The diameter of the granules is adjustable and is 2-12 mm. The device is also used to mix materials that are difficult to homogenize.

Product granulation is used in many manufacturing technologies. Due to the volume of production, the chemical industry dominates, but granulation is often used in food processing and technologies related to environmental protection engineering. In the chemical industry, molded fertilizer granules make it possible to obtain special properties regarding the speed of their dissolution.

Disc granulators are an example of devices used for the non-pressure granulation process, which takes place in a freely flowing layer of granulated material, sometimes with the use of so-called “binder”