The loading sleeve positioner manufactured by Biko Tech moves the loading sleeves in two axes, in a horizontal plane when loading trucks or wagons. The driver can stop the vehicle at the designated loading point, without having to place the transport tank in the central point of the loading area.

Most industrial plants processing bulk materials have a designated area with a loading sleeve installed, which allows the selected material to be transported to a truck, train or other vehicle.

The positioner is used to move the loading sleeve, facilitating docking of the sleeve outlet, e.g. to the flange of a road tanker, without the need to move it when the vehicle is not parked in the central point of the loading area. This is very important when the material transport tank has non-standard dimensions.

The loading bellows of the sleeve is positioned above the vehicle inlet by moving it to the left or right and front and back.

The positioner allows the driver to make corrections when the vehicle has been properly stopped in the loading area, but the boom position is not in the center of the loading inlet. Thanks to the Biko Tech biaxial loading booms, the driver does not have to move the vehicle with the transport tank. Loading sleeves equipped with positioners increase the speed and efficiency of loading in production plants and eliminate the need to move the vehicle after it is parked in the area intended for loading.

These devices can be used in any production plant, in any industry that focuses on reliable technological solutions, safety and comfort of employees and subcontractors, as well as devices that increase the speed and efficiency of production processes. By moving unidirectionally forward and backward in the X axis and left or right in the Y axis, you can precisely set the position of the sleeve over a train or truck – regardless of whether loading takes place in open or closed mode.

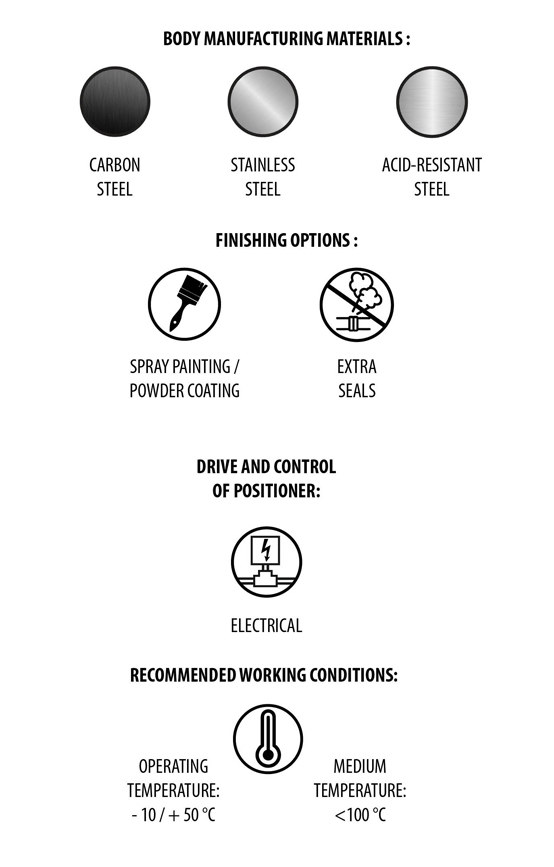

It is possible to install loading spouts from other manufacturers to the Biko Tech loading positioner by designing and using adapters enabling their work. The design and material of the loading positioners (black steel, stainless steel, heat-resistant steel) are adapted to the environment in which the device is planned to operate and to the physicochemical parameters of the material flowing through the device.

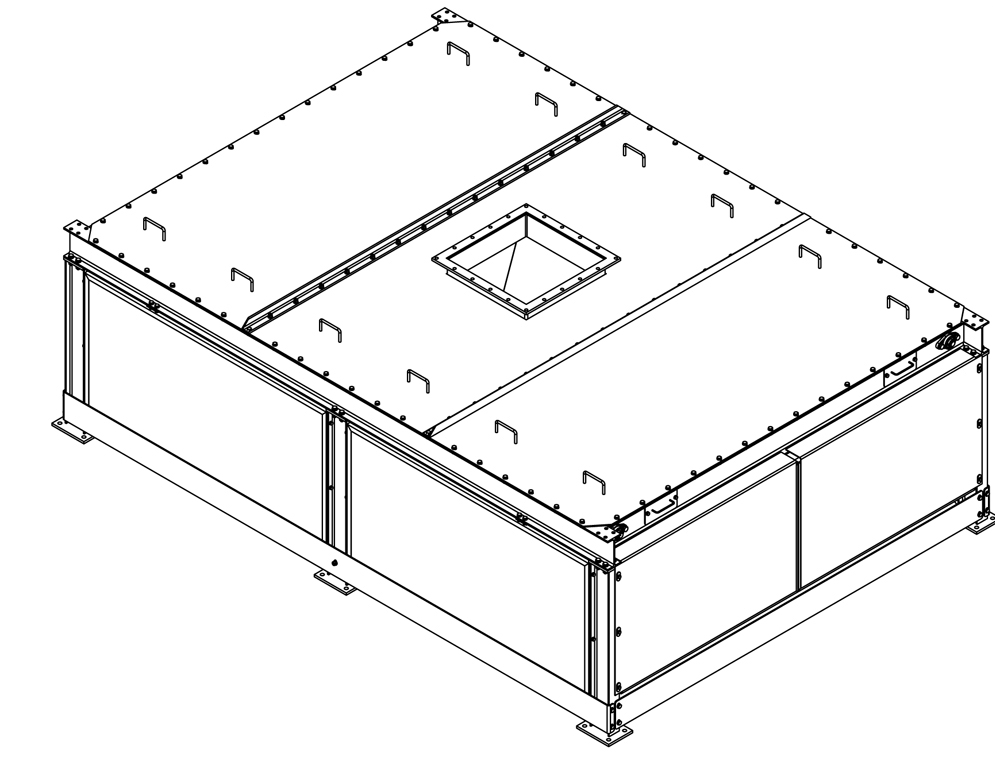

The standard operating temperature of the device is -10…+50 °C, while the standard temperature of the flowing medium is -20…+100 °C. The range of movements of the positioner can be any, depending only on the amount of space for installing the device. The range of movements and safety of use are ensured by limit switches. The device consists of a frame support structure equipped with a hopper sealed with nylon brushes located on its sides, arranged around the inlet edge. The brushes are elements of the dust seal. The hopper is also equipped with an inlet connection flange for the loading sleeve. The feeding hopper is driven by electric motors and moves on rails in both axes.

The positioner control is integrated with the loading sleeve remote control. After loading is completed, the positioner can return to its original location or remain in another selected place in the loading area.