Intensive mixing differs significantly from standard mixing methods in the industry. Devices for intensive mixing must have a much more durable structure and increased power. They are characterized by very high efficiency and short mixing time, in which a homogeneous mixture of excellent quality is obtained.

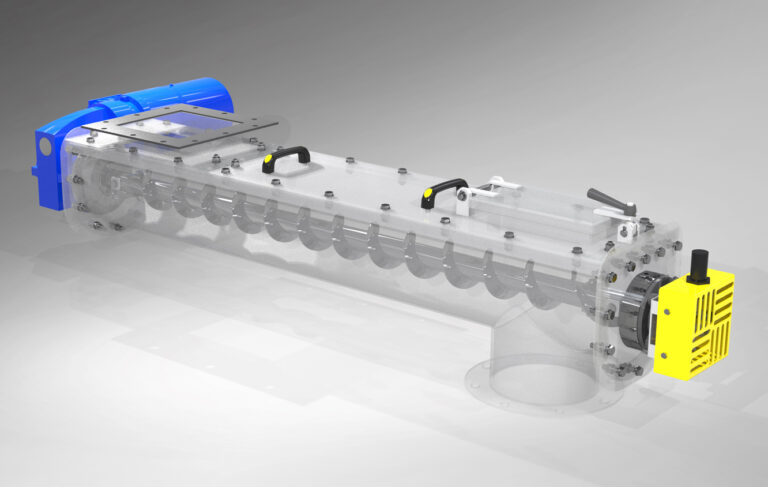

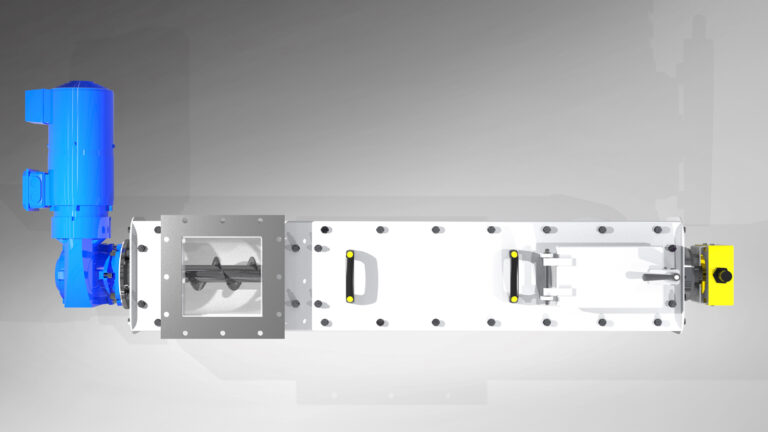

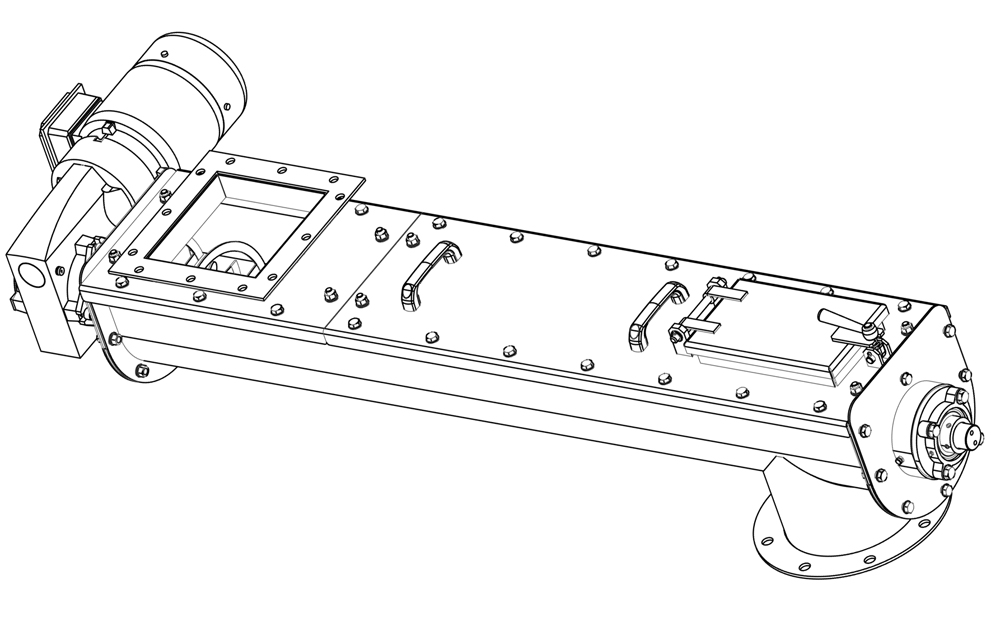

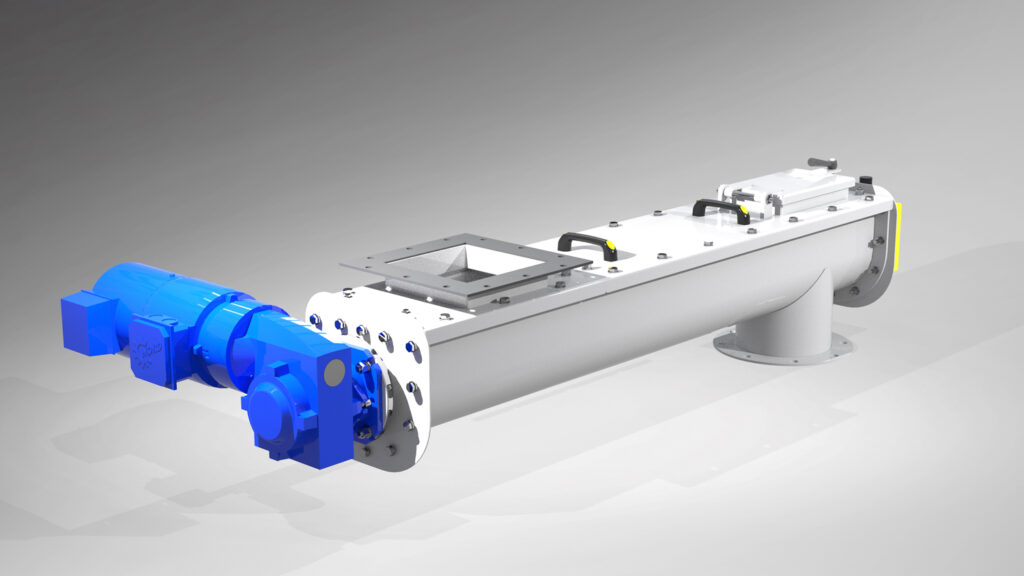

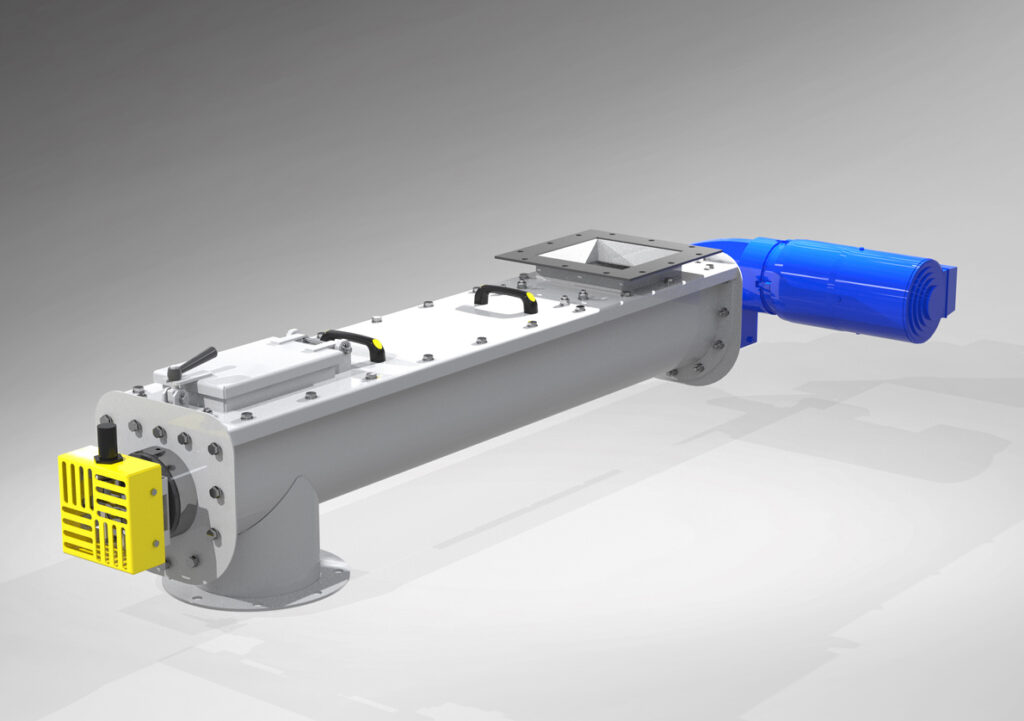

BKRM intensive mixers manufactured by Biko Tech are used for mixing powders and loose products. By adding a binding substance, the so-called binder, you can obtain granules with given physico-chemical parameters.

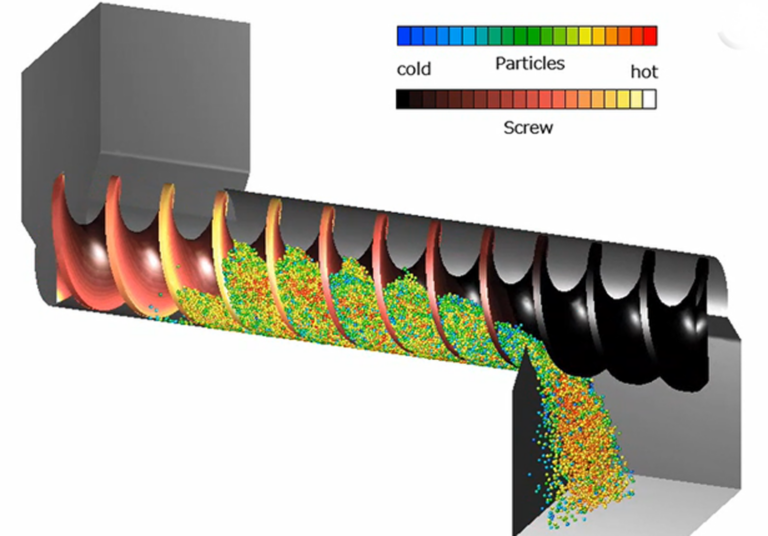

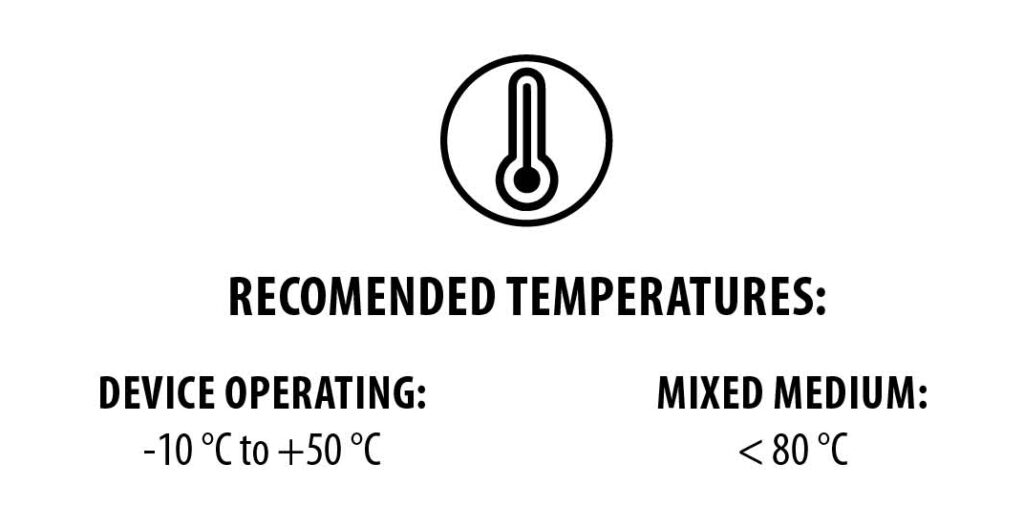

The mixing process takes place at an increased speed, where part of the energy is converted into heat as a result of friction. The optimal shape of the mixers is individually selected using digital DEM simulations, thanks to which the intensive mixers produced by Biko Tech cause perfect circulation of the mixed product.

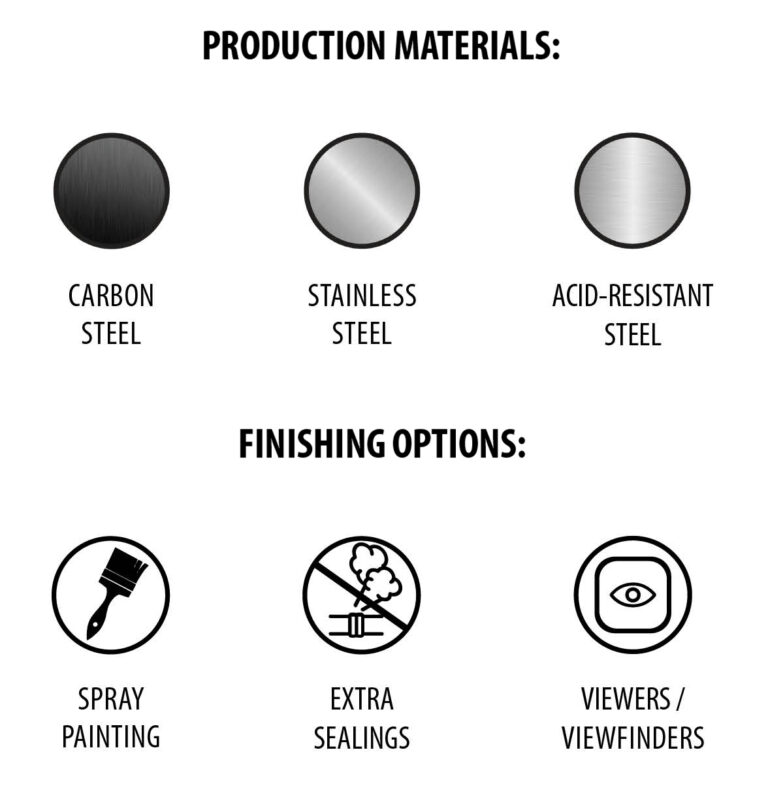

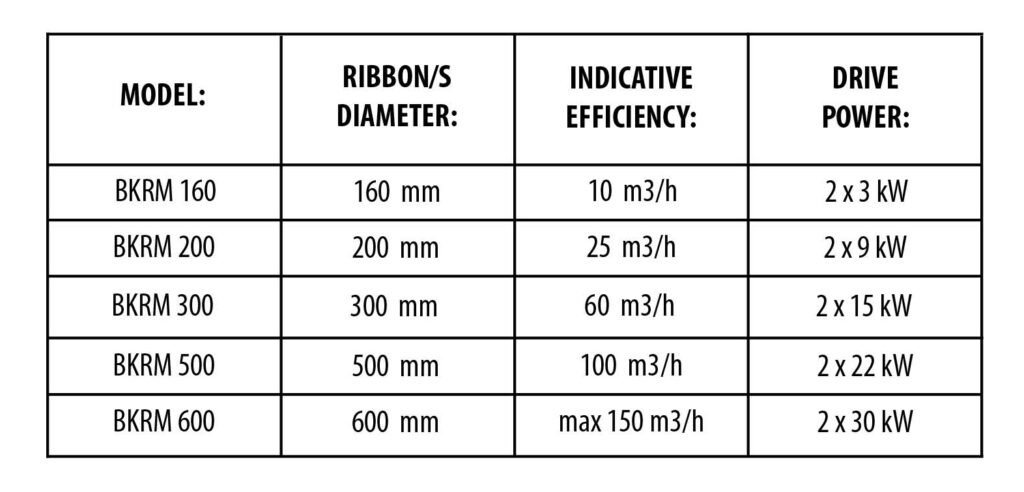

We offer BKRM intensive mixers in various sizes and capacities, made of various production materials, with parameters selected according to the needs of our customers, always adapting the mixer to the existing technological line in your production plant. Depending on the requirements of the mixing production process, the intensive mixer tank can be equipped with a heating or cooling jacket.