Hammer mills, also called beater shredders, belong to the group of impact shredders. These are extremely popular devices both for individual use, e.g. on farms, and for industrial scale applications in large production plants.

Hammer mills are devices used for uniform grinding of various solid, loose materials and raw materials, with a moisture content of up to 15%, including bio-products and biodegradable materials, to the desired fraction size, with low formation of fine dust fractions, e.g. coal, carbide, cement, malt, grain, hay, paper pulp, biodegradable materials and others. It is possible to grind raw materials with higher humidity, but this parameter has a very significant impact on the device’s operating efficiency.

Hammer mills are used in many industries, but most often they are used in the production of animal feed, feed pellets, pellets and fuel briquettes. These devices perfectly grind: previously dried sawdust, as well as chips, shavings, leaves, pieces of bark, grains, veneer, straw, stems and even small pieces of furniture boards, thus creating a homogeneous mixture, ideal for further technological processing in the production of e.g. : pellets or fuel briquettes. Whether you need ground flour, crushed seeds or other products, our BKBH hammer mills can be easily adapted to this purpose. Thanks to precise workmanship, you can be sure that the raw material will be crushed and ground with perfect evenness and efficiency.

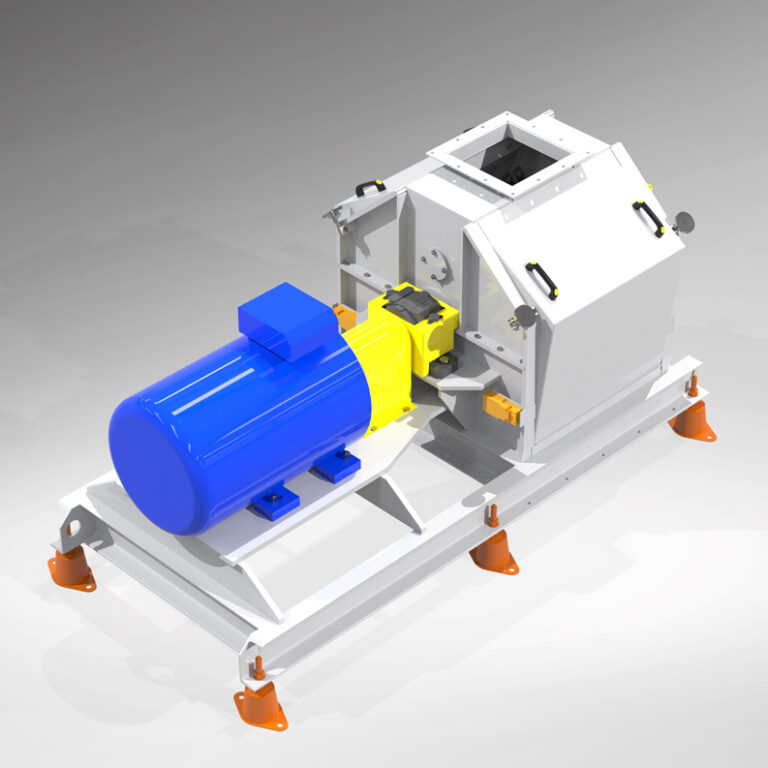

The operation of the beater shredder is very simple. The material is crushed in the main chamber of the mill, to which it is fed using a feeder. Grinding takes place by hitting the raw material using the hammers used in the mill and the raw material itself hitting the walls of the mill chamber. The size and regularity of the obtained fraction depend on the diameter of the holes of the sieve used in the mill. It is important that the materials entering the chamber are not contaminated. Otherwise, they may cause serious damage to the device. We recommend collecting the shredded material from under the mill using pneumatic transport, as this allows the use of a pneumatic separator to sift out stones and other impurities that may cause an explosion. The use of pneumatic transport will also increase the efficiency of the mill and allow the material to be conveniently transported to subsequent devices in the technological line.

Beater mills are equipped with sieves with a circular cross-section of meshes ranging from 5-10 mm in diameter. By using an appropriate sieve, we obtain a constant and appropriate fraction of the ground material and we can precisely regulate the degree of crushing of the material. Grinding during the briquetting and pelleting process allows you to increase efficiency and improve the quality of the final product and eliminates knots or larger pieces of wood that could damage the dies.

Our hammer mill is designed for maximum efficiency while minimizing production costs. We also understand that durability is crucial in an industrial environment, which is why our mill is made of durable materials and carefully tested to ensure long-lasting and reliable operation, even under intense conditions.

The quiet operation of the device is also a huge advantage. Our team of engineers made sure that the mill was not only efficient, but also easy to operate and maintain. Thanks to the intuitive interface and available maintenance tools, keeping your mill in perfect condition is simple and quick. Replacing the hammers and screens used in the mills is very efficient, thanks to which the hammer mills can operate almost without technological interruptions. Another undoubted advantage of the mills is the low level of vibration of the device, which ensures comfort during operation. Our priority is to ensure safe work for your employees. Our hammer mill is equipped with advanced security and emergency stop systems that minimize the risk of accidents and disruptions at work.