Granulation, also known as agglomeration, pelletization, is the process of combining small particles such as dust, powders or ashes into larger aggregates (granules), with specific mechanical strength and granule size above 1 mm. The agglomeration or granulation process itself is carried out by wet granulation with the addition of liquid or alternatively by hot granulation.

Granulation is used to obtain a convenient final form of the product that is acceptable to users. Raw materials or semi-finished products are often granulated to facilitate or even enable their use in appropriate technologies.

Product granulation is used in many manufacturing technologies. Due to the volume of production, the chemical industry dominates, but granulation is often used in food processing and technologies related to environmental protection engineering. In the chemical industry, molded fertilizer granules make it possible to obtain special properties regarding the speed of their dissolution.

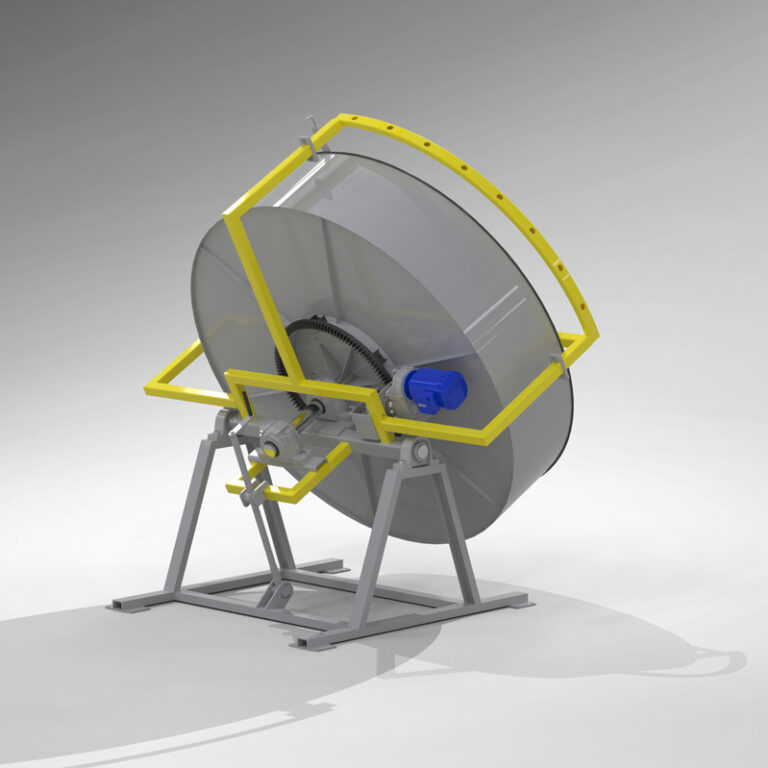

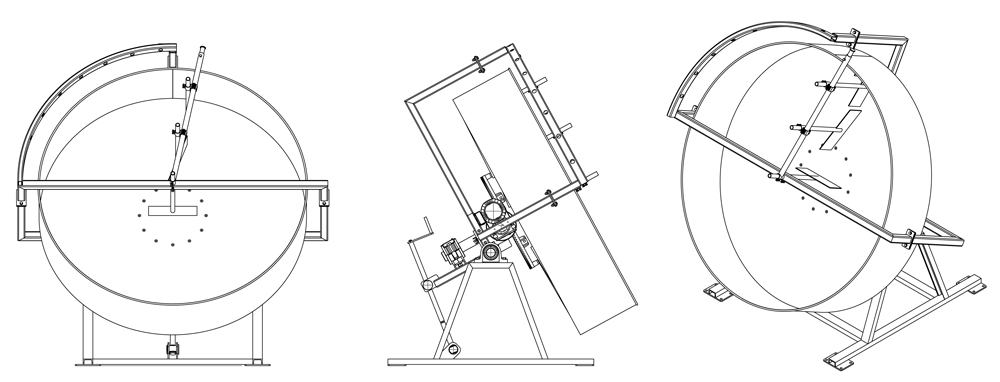

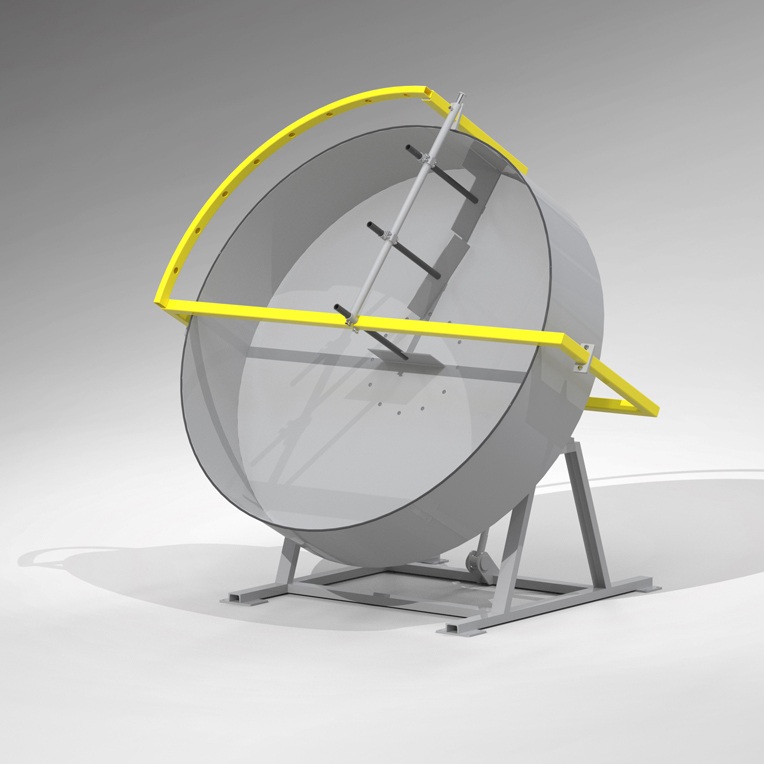

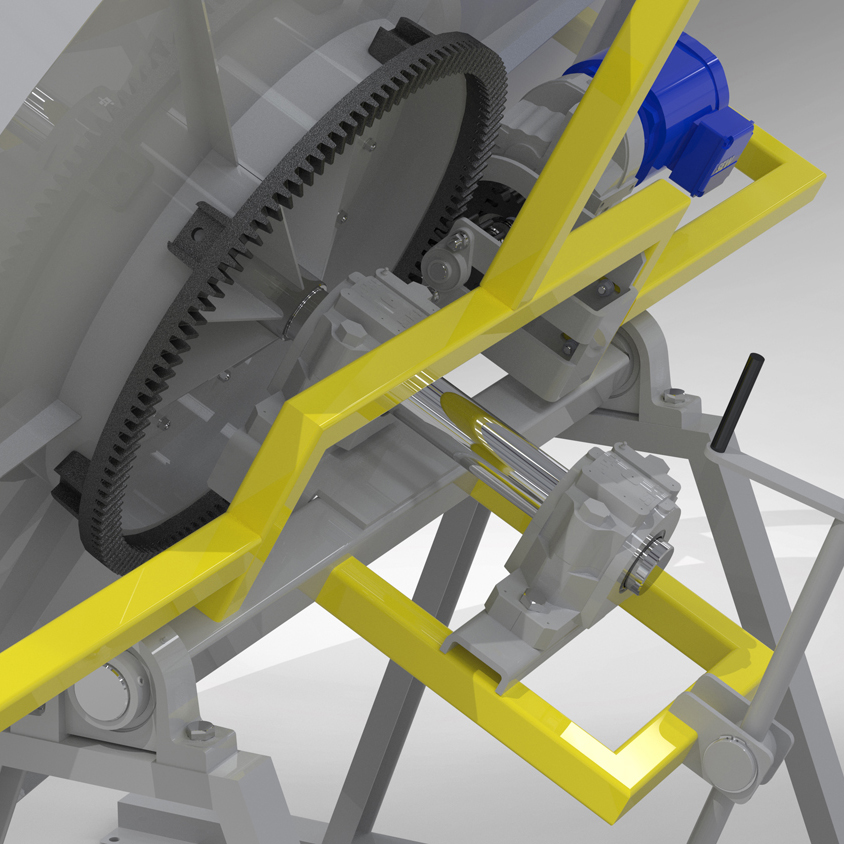

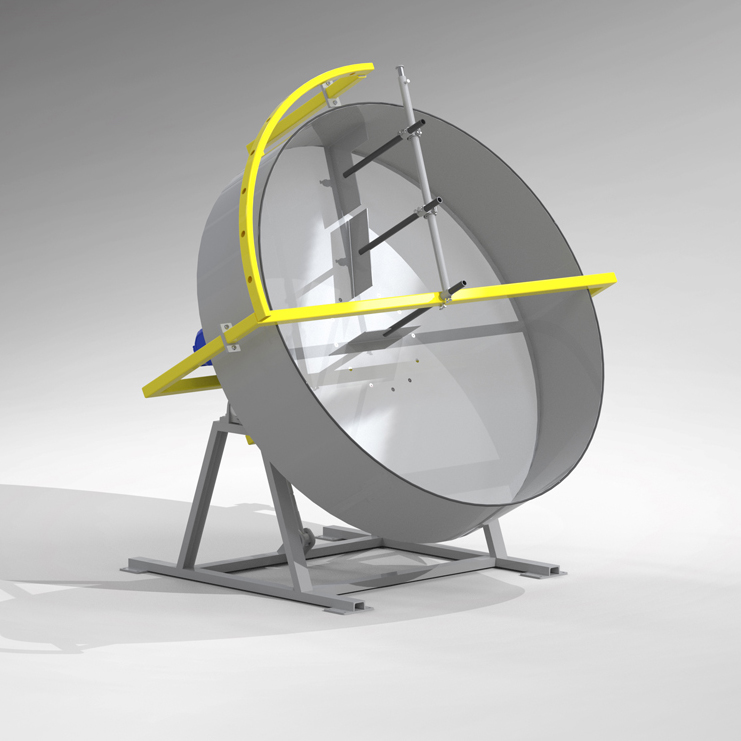

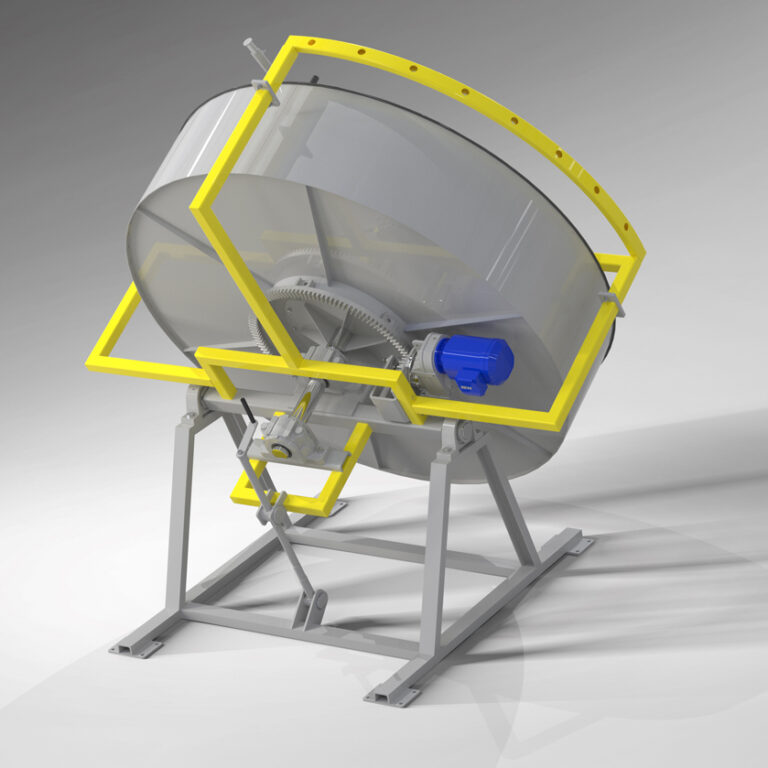

Disc granulators are an example of devices used for the non-pressure granulation process, which takes place in a freely flowing layer of granulated material, sometimes with the use of so-called “binder”

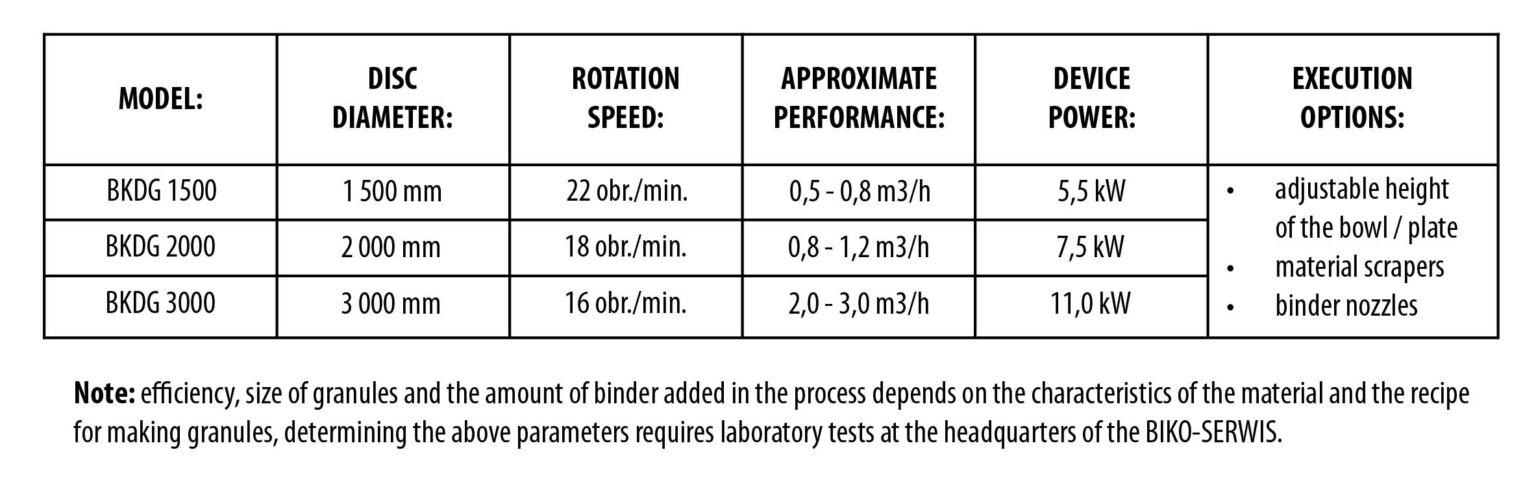

Disc granulators manufactured by Biko-Serwis are used in many pressureless granulation processes. The main areas of application are: building materials, ceramics, energy, municipal waste, artificial fertilizers, foundry and environmental protection.

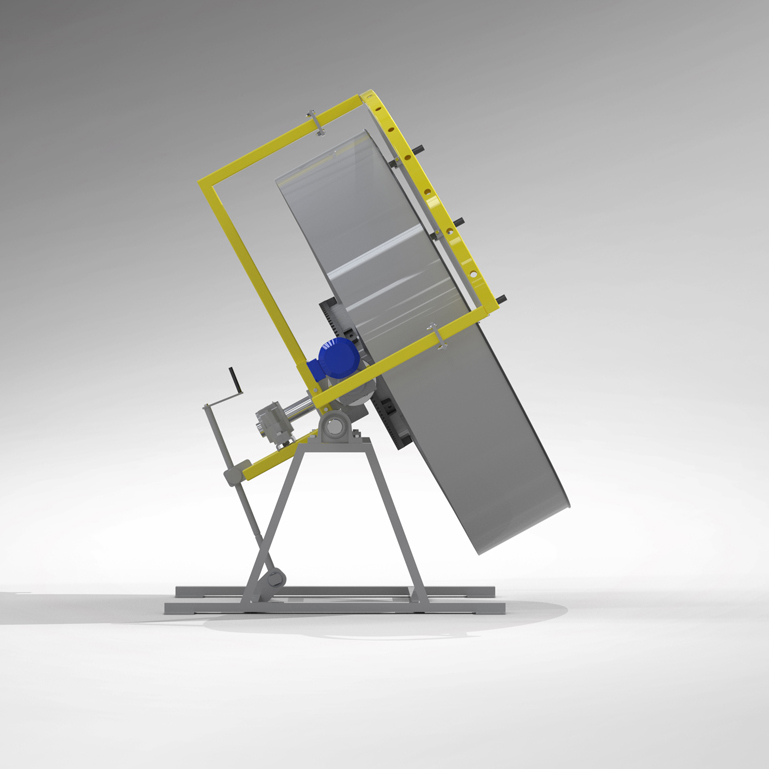

Principle of operation of the Biko-Serwis disc granulator:

Loose material is fed onto a rotating disc, while a binder is introduced into the mixture through nozzles. By appropriately setting the moving scrapers, the material is surrounded on part of the surface of the granulator disc and the agglomeration process takes place. The angle of operation of the granulator is variable, as is the angle of setting the nozzles and scrapers.