A central vacuum cleaner is not so much the name of the device but of the entire installation, which involves installing many connection points (sockets) in the walls and ceilings, which are connected to the main tank. The principle of operation is based on the vacuum pneumatic transport of bulk materials (powders, small grains) and liquids by lifting them in an air stream flowing in a closed pipeline.

In many industrial sectors, technological and production processes generate a large amount of waste/loose material/dust, which must be removed while it is being generated. Working with hazardous dust requires the highest level of safety from the equipment. Industrial vacuum cleaners used in many industries guarantee that the work environment is kept in proper condition.

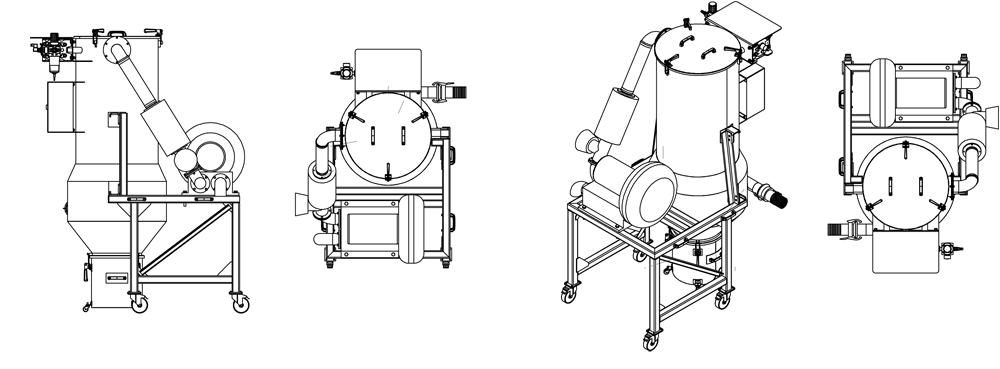

The main element of the system is the central unit, which creates a vacuum and sucks in air along with dust and small impurities. The housing contains a motor and a filter part responsible for the separation and storage of dust collected during cleaning. The separated design allowed the use of a larger and more efficient cyclonic separator and the use of an additional hair filter, not found in compact devices.

A central vacuum cleaner does not require us to move a relatively large and heavy device around different floors of the building, as is the case with traditional vacuum cleaners.

Central vacuum cleaners produced by Biko Tech are adapted to customer requirements. Power consumption depends on the power of the drive used; it is not much higher than in the case of traditional vacuum cleaners with higher power. We gain energy savings because we remove pollutants faster.

Central vacuum cleaners are ideal solutions for large areas, industrial plants, industrial halls, office buildings, hotels, restaurants, guesthouses, residences, museums and other public facilities. Unlike regular vacuum cleaners, which are mostly very noisy when turned on, central vacuum cleaners are simply quiet. Only the central unit, which is usually located in a technical room, basement of a building or garage, produces noise. We can design devices in both stationary and mobile versions. They can work as mobile suction units mounted on cars and trailers.

BKVC units are dedicated to large installations where high efficiency of the entire installation is required. Pipes transporting the air mixture together with pollutants are made of special, antistatic materials that prevent dust particles and other pollutants from sticking, and therefore from the multiplication of bacteria.

The BKVC vacuum cleaners for industrial applications proposed by Biko Tech are the highest quality equipment, thanks to which they effectively help maintain hygiene and continuity of processes in production plants, power plants, steelworks, cement plants, mills, feed factories, as well as in logistics centers, warehouses and workshops.