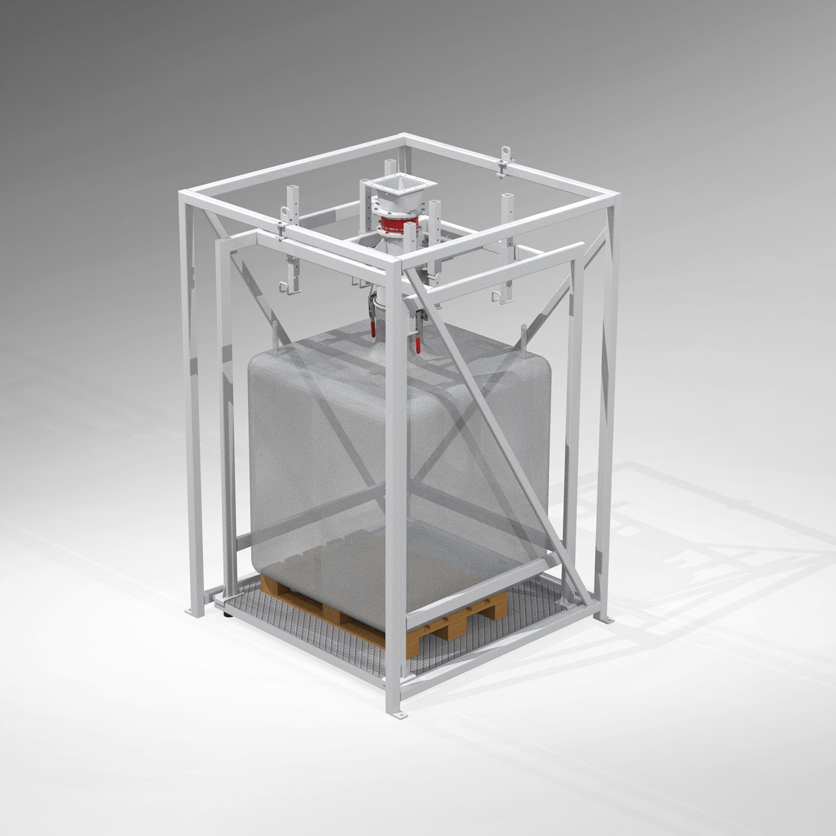

BIG-BAG loading and unloading stations are used in many groups and sectors of industry and construction. They are used for dust-free reloading in the automatic, closed circulation of loose and granulated materials. The stations can be used for both unloading and loading of loose, granulated and fine-piece raw materials with minimal involvement of the production plant staff. If the loading/unloading process is not automated, it takes a lot of time and requires the involvement of many employees.

We configure stations in accordance with customer requirements, product properties and storage features, and environmental conditions.

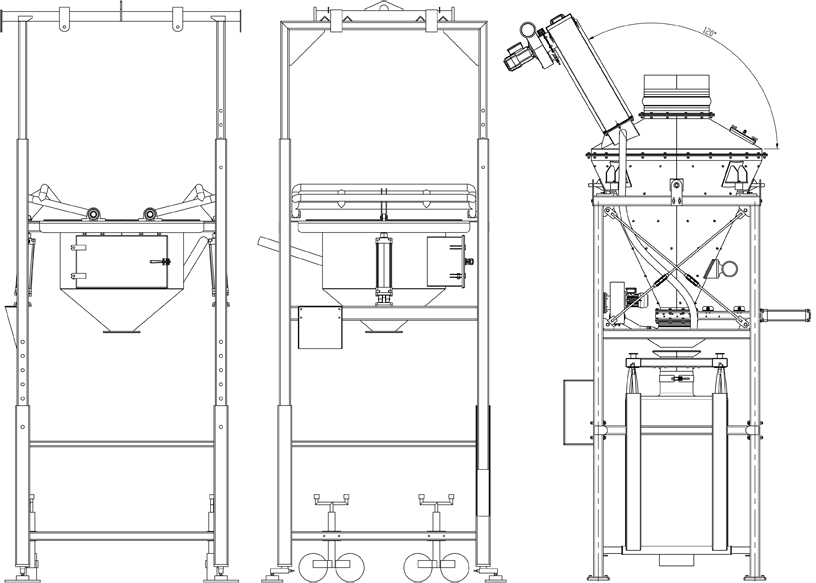

The design of the Biko Tech station always guarantees safe and convenient loading and unloading, ensuring high efficiency and cost savings, even in the case of materials that are difficult to unload, and also offers the possibility of safe opening of bags.

Our solutions protect the production area against dust and avoid product leaks and surface contamination around the station itself. We offer appropriate docking systems – from standard ones intended for safe bulk products, to specialized systems protecting against highly reactive substances that require process isolation to ensure the safety of both the product and production workers.

The BIG-BAG unloading station is an opportunity to significantly improve your production line. Automated unloading and loading stations produced by Biko Tech significantly facilitate and speed up the work of both industrial plants and activities related to warehouse management. Our stations are characterized by high efficiency and reliability.

FIBC / BIG BAG, also known as large-size bags, are flexible containers made of polypropylene fabric. Such bags can be used to transport and store both fine and loose products intended for the food industry, granulates and substrates used in the chemical industry, as well as all types of waste and loose construction materials.

If necessary, we integrate stations, among others: with service platforms, transport systems, screens, shredders or industrial weighing systems. The attached bag is connected to a feeding hopper that directs the product to a screw conveyor, through which the product is then transported to other machines. The operating speed of the screw conveyor is smoothly regulated using an inverter, depending on the system efficiency that the customer wants to achieve.

Appropriate docking systems – from standard, designed for safe bulk products, designed to protect the production area from dust, to specialist systems protecting against highly active substances requiring isolation of the process to ensure the safety of both the product and employees. Our stations are characterized by high efficiency and reliability.

Using Big Bag stations speeds up processes and minimizes the need to engage many production employees. The Big Bag unloading station is a chance to improve your production line.